Buying a 3D Printer: 5 Essential Questions to Ask Yourself

You are a professional or a maker and you have decided that you are interested in buying a 3D printer. You’ve seen how the technology can help you make custom parts, lower cost prototypes or design components faster, so it’s time to take the next step: selecting the right 3D printer! But what do you need to know before making such a decision? There are a multitude of brands and prices on the market that can present obstacles in your purchasing process.

To help you make the best decision, there are at least 5 questions that you need to ask yourself to help you define the brand, budget and technologies that are right for you. Before you start asking yourself these questions, it is also important to know what you will be using your 3D printer for and what you already know about 3D technologies today.

Buying a 3D printer: what is my budget?

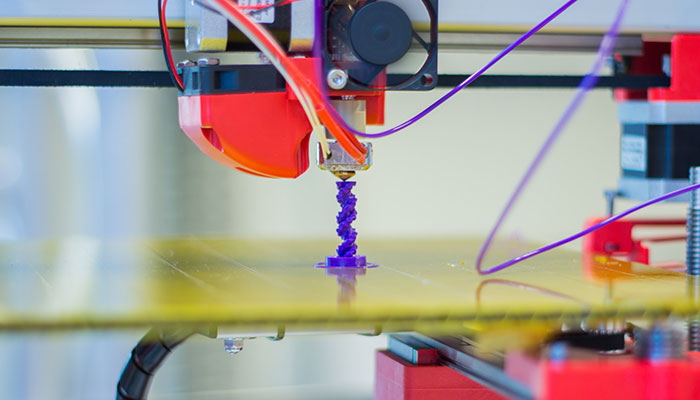

Once you have defined the purpose of your 3D printer, you need to know how much you are willing to spend on this new machine. There are different price ranges: for $200, you will be able find FDM 3D printers in kit form that you will have to build yourself, many from Chinese brands like Creality or Anycubic. If your budget is higher, from 1000€, you can turn instad to plug & play 3D printers, which are ready to use and can be started with a simple button.

If your budget exceeds a thousand euros, other techvnologies are available. Between $1,000 and $5,000, you will find SLA and FDM 3D printers that have a very high print quality. Between $5,000 and 30,000, you would opt for industrial FDM machines or more specialized SLA printers for sectors such as dental or jewelry. You will also find selective laser sintering (SLS) machines, which have gained in popularity over the years and that are particularly useful in certain industries.

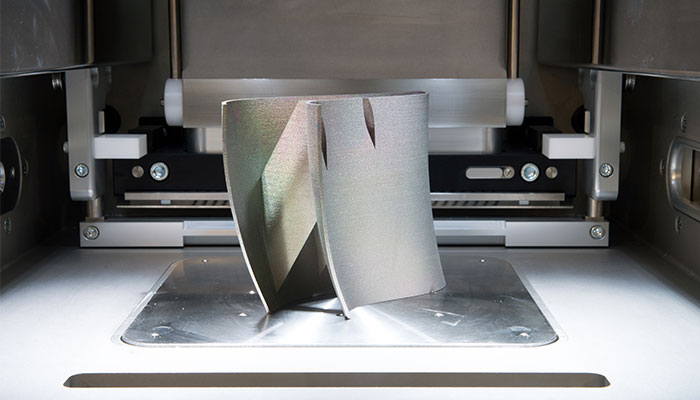

Finally, the last price range starts from $80 000 and more. Such a budget will allow you to access technologies such as HP’s Multi Jet Fusion, or Direct Metal Sintering (DMLS) which allows you to make metal parts.

HP printers

What material am I interested in using?

Now that you know how much you want to spend, you also need to choose your printing materials. A technology like FDM is mainly used with plastics, with filament spools available from $20 depending on the type of specs you are interesting in – there are more technical filaments that can reach $350 per kg. If you are looking at SLA technology, you will use photopolymer resins starting at $70 per liter. However, it is important to note that there are not yet many colors available today, although some manufacturers are trying to develop more.

If you are considering more industrial applications with your machine, you will opt for SLS or DMLS technologies. In the first case, you will use mainly polymer powders and in the second, different metals and metal alloys also with a price that will vary according to your needs.

Buying a 3D printer: what print volume do I need?

It is important to know what you want to print and in what quantity; those printing in small runs would not have the same needs as those printing in larger quantities. This is where you need to consider whether the cheapest machine is really the best solution. In some cases, you will have to spend a little more to get a larger print volume.

However, there are FDM technology machines with a generous print volume at an affordable price or even large format machines like those from Bigrep. In the case of SLA or SLS technologies, 3D printers generally don’t have as much print volume. For metal 3D printers, sizes vary depending on your needs and investment, but it is already possible to have beautiful industrial parts.

What to ask before you buy: what is my 3D printing skill level?

It’s important to know where you stand with respect to 3D printing: are you a beginner? Do you have some technical skills in this area? The degree of knowledge in additive manufacturing could influence your choice of printer.

There are 3D technologies that are suitable for everyone; for example, beginners can use FDM technology, they will find Plug and Play machines, which combine hardware and software. The printer is already assembled and it is possible to start printing directly. On the other hand, there are DIY kit 3D printers, which will allow you to print what you want but that you will have to assemble the machine yourself. If you are familiar with 3D printing and have skills in mechanics, 3D modeling, etc., you can opt for more professional technologies such as SLA, SLS, Multi Jet or DMLS, which require additional training and care to fully understand the process.

An important point to consider is using the right 3D software. With less complex projects, you can use very simple 3D software, but as the complexity of your project increases and you need new technologies, it is not uncommon for CAD needs to become more complex as well.

SLA technology requires more time for post-processing

Also remember to assess how much work you are willing to accept after the actual printing process; post-processing is more or less heavy when tackling 3D technologies. Some require more work than others; FDM, for example, often involves removing the support material if it exists and sometimes processing to reduce the layering effect. SLA technology requires more elaborate work in terms of post-processing, while for SLS, you’ll need machines to dust and process the parts. For metal 3D printing technologies, the post-processing is obviously much more time consuming.

Where can I buy a 3D printer?

Now that you have clarified your project and know what type of 3D printers you want to go for, there is one last question: where to buy it?

In terms of brands, there is no shortage of choice! Our comparator can help you choose the right 3D printer as you can select what you want from the different criteria you have just considered – technology, material, price range, build volume. The filter function will make your search much easier. If your needs go a little further, if you want an industrial 3D printer but are not sure, you can contact specialist distributors via our directory. You will then be able to receive all the advice you need to invest in the right machine. Don’t hesitate to watch the video below to use the machine comparator:

What do you think a buyer should consider before buying a 3D printer? Let us know in a comment below or on our Facebook and Twitter pages. Don’t forget to sign up for our free weekly newsletter, with all the latest news in 3D printing delivered straight to your inbox!