Researchers Use New Compound, MXene, and 3D Printing to Improve Satellite Communication

3D printing is gaining ground in many areas, including aerospace and defense. Already, additive manufacturing has been used to produce parts for Boeing’s combat helicopters and satellite antennas in space. In addition, research projects on the subject of 3D printing are constantly coming to light. In one such case, researchers at UBC Okanagan (UBCO), together with Drexel University in Philadelphia, Pennsylvania, have developed a new compound – MXene – which has great potential for 3D printing antennas in the space and satellite industry.

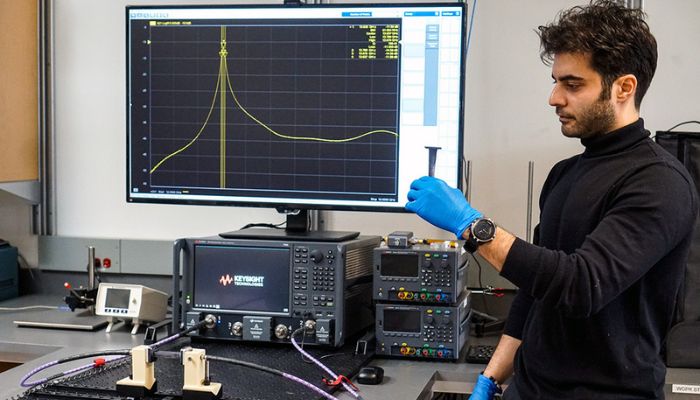

As mentioned, the research project was a collaboration between scientists at the A.J. Drexel Nanomaterials Institute at Drexel University and UBCO. The Department of National Defense, the Natural Sciences and Engineering Research Council and the United States National Science Foundation supported the research. In it, Mohammad Zarifi, A researcher in UBCO’s Microelectronics and Gigahertz Applications Laboratory (OMEGA) and associate professor in the School of Engineering, and his team have set out to develop advanced communication components. The special thing about them is that these components are 10 to 20 times lighter, cheaper and simpler in design than conventional metal ones, all without having to sacrifice performance.

A prototype of a 3D printed, MXene-coated component

The 3D-printed objects developed by the scientists from the fusion of the MXene compound and a polymer have the potential to advance the manufacture of telecommunications antennas and other connecting elements. As a result, they could significantly improve communications technology – including antennas, waveguides (used to conduct sound and optical waves in communication devices) and filters. Traditionally, these have been made from metals such as silver, brass and copper, but MXene shows significant promise.

MXene and 3D Printing Combination Could Create Better Satellites

The MXene developed by the researchers represents a two-dimensional family of materials that also includes titanium carbide, which is characterized by its electrical conductivity, according to Dr. Yury Gogotsi, Director of the A.J. Drexel Nanomaterials Institute at Drexel University in Philadelphia. It is possible to imagine MXene as nanometer-thin conductive flakes that can be dispersed in water like clay, continues according to Dr. Gogotsi. The material can be applied to almost any surface from the dispersion in pure water without additives. After drying in the air, it can make polymer surfaces conductive. It is like metallization at room temperature without melting or vaporizing a metal, without vacuum or temperature.

And the potential of the devices is immense. The researchers believe that the capability of a lightweight, additively manufactured device could impact the design and manufacture of electronic communication devices in the space and satellite industries in the future. Indeed, the lightweight MXene-coated polymer structures even have the potential to replace traditional manufacturing methods such as metal machining to produce channel structures.

Dr. Zarifi concludes, “While there is still additional research to be done, we’re excited about the potential of this innovative material. We aim to explore and develop the possibilities of 3D printed antennas and communication devices in space. By reducing payloads of shuttle transporters, it gives engineers more options.” For more information, click HERE for the UBCO article.

What do you think of the use of MXene and 3D printing for better satellite components? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: UBC Okanagan