What Is the Current State of 3D Printing in India?

When we talk about countries where 3D printing is present, what most comes to mind is the USA, Western Europe and China. These are where we see the largest established base of 3D printers as well as the biggest number of manufacturers, with China especially showing incredible growth. But these are not the only areas of note for additive manufacturing. India, the country with the largest population (1,409,128,296 by recent counts), is quickly catching up and is becoming a major region for 3D printing in Asia.

For quite a few years now, we have seen the rapid expansion of additive manufacturing in India. Indeed, the projects coming from the country as well as the presence of home-grown 3D printer manufacturers has grown significantly. But what exactly is causing this? How has the use of these technologies grown in the country? To better understand the current state of the 3D printing market in India, we spoke with a few experts.

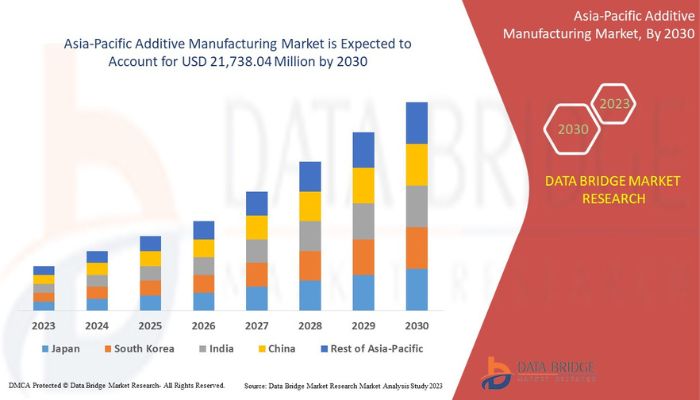

In general, Asia-Pacific seems to be one of the fastest growing regions for additive manufacturing, led by China. Out of all the countries, India (grey in the image) is also showing immense growth coming (photo credits: Data Bridge Market Research)

Where Is 3D Printing in India Now?

To understand 3D printing in India, it’s important first to look at some statistics. A study from XResearch on India’s 3D printing market showed that in 2022 its revenue surged to $111.0 million in 2022 and was expected to further accelerate until it reached an estimated $705.1 million by 2030, a CAGR of 20.3%. In comparison, the U.S. market was worth $4.46 billion in 2022 but will grow at a rate of 15.7% in the same period according to Spherical Insights.

And this growth has been clear for quite some time. in 2021, an EY study reported the growth of 3D printing in India. Mahesh Makhija from the company explained that “India has seen increasing adoption of 3D printing technologies with growth rates over 30% year-on-year across materials. The industry has evolved from being a prototyping tech to end use production, with metal AM (additive manufacturing) leading the course.”

The experts with whom we spoke also agreed with this, starting with Kuntesh Radadiya, General Manager at STPL3D, one of the major 3D printer manufacturers in the country and the first to create their own “Made-in-India” SLS 3D printer. He notes, “Starting with first tier cities like Delhi, Mumbai, Bengaluru, Surat, Hyderabad, Coimbatore, and Pune, the demand for 3D printers in India is beginning to pick up.”

He further mentions three prominent segments that are interested in 3D printers and the types of solutions they prefer. This includes globally renowned 3D printer manufacturers who increasingly have authorized resellers and distributors in the country, locally manufactured printers (notable for their cost advantages due to localized production of components) and printers imported from countries with low manufacturing costs.

He adds, “Each category attracts a distinct set of buyers and sellers. Typically, industries with stringent precision requirements favor printers from the U.S. and Europe, while hobbyists and SMEs gravitate towards affordable alternatives.”

There are a growing number of home-grown 3D printer manufacturers, including STPL3D (pictured here with their industrial SLA solution) who also launched India’s first SLS 3D printer (photo credits: STPL3D)

But what about the types of technologies available? Well, currently there are a number of different 3D printing technologies in India including extrusion, vat photopolymerization, selective laser sintering and selective laser melting (metal). Selective laser melting especially has received significant attention with India’s largest 3D printing service bureau, Wirpro, recently investing in the SLM systems. Indeed, it seems all current AM processes can be found in some form in the country, including the recent development of an Indian EBM 3D printer, though certain remain more popular than others. The country has also become a hub for construction 3D printing, as we will cover later on.

Radadiya expands, “Overall, the AM industry in India is witnessing significant growth, with FDM and SLS being the most popular technologies. The increasing demand for rapid prototyping, customized tools, and unique designs in various sectors is creating a positive outlook for the future of AM in India.” He continues “The rising demand for customization, lightweight components, and complex geometries is further propelling the growth of Metal AM in India.”

Investment in 3D printing technologies has also been marked. Most especially from the Government of India who in 2022 unveiled the National Strategy on Additive Manufacturing. In this strategy, the mission is to position India as a global innovation and research hub for AM. To do this, the aim the Ministry of Electronics and Information Technology (MeitY) to increase India’s share in global additive manufacturing to 5% by 2025. Furthermore, the country will aim to achieve targets such as the creation of 50 India-specific technologies for materials, machines and software, 100 new AM startups, 500 new products and produce new jobs for skilled workers who have been trained in 3D printing.

The Importance of Service Bureaus

However, 3D printer manufacturers do not make up the majority of the 3D printing business in India. Rather that honor goes to service bureaus. And there are a number of notable players in India including Imaginarium, Rapid 3D, Think3D, Wirpro3D and Vektor3D Systems, among many others.

This of course means that these bureaus are incredibly important in the country and are key to helping drive adoption of AM, shown as well by the Government of India’s support of them. Priyesh Mehta, Director of Imaginarium Rapid, comments, “The relevance and importance of 3D printing service bureaus still remains high in India, a country where people would usually prefer to ‘try first and then buy’. Also, the pace at which new 3D printing technologies are introduced for commercial use also makes a compelling case for OEM’s and part manufacturers to collaborate with service bureaus.

Wirpro worked together with the Indian Institute of Science (Bengaluru) to open a new Center of Excellence in India dedicated to researching next-gen metal AM technologies (photo credits: IISc Bangalore)

He continues, “Several OEM’s are using the make vs. buy decision making model and are preferring to use in-house machines for qualification of new use cases and external capacity with service bureaus for production.”

Given that it is through service bureaus that some of the most exciting and well-known Indian 3D printing projects came to be, such as the Guiness World Record-holding diamond ring made by Imaginarium back in 2020, this should come as no surprise. Furthermore, it seems likely as well that they will continue to be important in the country. Not the least because as it stands right now, they outnumber solution providers and have been involved with projects from the government including the country’s first metal 3D printer and the development of the National Centre for Additive Manufacturing (NCAM) in Hyderabad.

Notable Applications in the Country

As the use of 3D printing has grown in India, so too have the applications for which it is used. Of course, the most visible has been in construction. Over the past few years, a number of impressive projects have come out of the sector including a 3D printed post office and multistorey buildings.

Manu Santhanam, Professor in the Department of Civil Engineering at IIT Madras, has worked with Indian startup Tvasta and is an expert in 3D printable concrete. Together, he has been involved with both Tvasta and L&T. In terms of current projects in India, he explains, “Currently, L&T is also involved in the construction of a set of buildings in Chandigarh, as well as villas in Bangalore. Tvasta has also been getting several niche projects, some of them in combination with M/s Godrej Construction, Mumbai. Another start-up, called MICOB, based out of Gandhinagar, has been executing 3D printed buildings for the defense sector.”

Why is it so useful? Well, as we see in other countries, the potential for 3D printing is most clearly seen for the creation of buildings with complex geometrical designs as well as its potential to address housing crises. Professor Santhanam expands, “Currently, AM in construction is being looked at for the creation of niche facilities, with geometrical designs that are not easy to do with conventional construction. 3D printing applications will continue for special buildings. But after the guidelines for construction are properly established, it is expected that 3D printing will also work its way into mass housing, provided the scale is large enough to achieve the economy.”

One notable example of construction 3D printing in India is a recently unveiled post office (photo credits: L&T)

Still, that does not mean that it is already well-established. Though there are a couple of major players, competition is still scarce. Building company L&T is by far the most prominent in this space.

Professor Santhanam notes, “Apart from L&T, no other large building company has entered this domain. On the other hand, after Tvasta and MICOB, several other start-ups including Simpliforge and DeltaSys have come into the 3D printing scene. Overall, 3D printing is still at an early stage, primarily because of the lack of regulatory guidelines – these are being developed currently through the Bureau of Indian Standards.” A trend that we have seen in other countries of the world as well, including the United States.

That said, it is undeniable that construction 3D printing has taken a foothold in the country and its potential is impressive. It is especially useful for creating customized buildings quickly as well as providing construction support to areas that are difficult to access or where there are limited resources including low availability of labor. This seems likely to be one of the sectors where there continues to be sharp growth of 3D printing in India, such as in Dubai where 3D printing is starting to become a more mainstream construction method.

Other 3D Printing Applications in India

But even if the use of 3D printing in India’s construction industry is impressive, it can hardly be said to be the only application. In fact, there are many industries where 3D printing is being seen as a complement to other technologies that are also present in India, including AI and machine learning. A fact that has also been recognized by MietY.

Mehta explains, “3D printing in India has a very high growth potential, mainly due to India’s growing manufacturing system led by automotive, space, electric mobility and drones. The push from prototyping to production is mainly led by original equipment manufacturers and service bureaus to get the maximum value out of key Additive Manufacturing offerings such as design freedom and inventory-less production. The highest number of installed bases of 3D printers would be in research and universities, jewelry and dental, respectively. We see it evolving steadily in the last three years where core manufacturing industries have identified use cases to complement (and not replace) casting, machining and forging.”

Healthcare is one of the sectors where 3D printing is growing in India. For example, these models made at the Max Super Speciality Hospital, Saket (photo credits: Materialise)

Radadiya affirms this, confirming “Laser Powder Bed fusion (both metal and polymer) have been favored to qualify and manufacture end-use parts for aerospace, defense, mobility and energy. The stability and repeatability at scale of these technologies make them a natural choice for OEMs, service bureaus and even researchers. Key applications which have been seen tremendous growth in the last few years have been in a) Drones (perfect test bed and application for high mix and low to mid volume) b) E-Mobility (faster product development cycles with Additive Manufacturing and AM-led tooling) c) Energy (On-demand spare parts) d) Healthcare (Orthoses & Prosthetics, Implants, and medical devices)”

The importance of healthcare and dentistry especially has also been shown in recent projects. For example, Nanavati Max Super Specialty Hospital, based in Mumbai, announced the opening of a 3D printing lab that will be used to facilitate high-precision surgeries, particularly ones related to oncology. Furthermore, 3D printing has been used in India to create implants to treat black fungus, a debilitating disease that has spread in the country since the start of the COVID pandemic.

The Obstacles to Overcome

Of course, that is not to say that there are not still obstacles to adoption. In the announcement of India’s AM strategy, the government notes that the lack of formal industry standards, lack of skilled manpower, uncertainty in the regulatory and legal framework and the possibility of more technology rendering skilled workers obsolete as key challenges. These reflect what we have seen across the board in other countries including the USA.

Radadiya agrees with this assessment particularly in terms of the lack of skilled workforce who have been trained in AM technologies. He adds as well that high initial investment costs for AM equipment and materials and limited availability of standardized materials and design guidelines are other obstacles to adoption.

Universities in India like IIT Madras are offering certificiations in additive manufacturing to address issues like lack of skilled workers (photo credits: IIT Madras)

He notes as well specific challenges related to SLM 3D printing, commenting, “Overall, SLM metal 3D printing holds immense potential to transform various industries in India. However, addressing the challenges related to cost, skilled workforce, and standardization will be crucial for its widespread adoption and long-term success.”

That being said, between government support and the interest that many universities in the country are showing towards the technologies, these are issues that can certainly be resolved in the coming years. IIT Madras in particular has become a hub of AM learning, as this is not only the center of Indian 3D printing construction but has also shown considerable progress in terms of medical 3D printing.

The Future of 3D Printing in India

As should be clear, there is still room for the growth of 3D printing in the country. But if it continues on this same track, it seems that India may become a force to be reckoned with in coming years. Adding to this the serious interest that both the academic sector and government have in AM, it is likely that we will see an explosion in research and applications in the coming years.

This is echoed by Mehta, who concludes, “India is the world’s third largest startup ecosystem (with 112,718 government-recognized startups across the country). The shift from only importing into India, to making in India, and to now, designing and making in India has picked up steam significantly after COVID-19. Also, government policies like production linked incentive schemes are encouraging more investments and focus on India’s manufacturing eco system. With India’s “Atmanirbhar Mission” (self-reliance for manufacturing), several government agencies are now preferring “Made In India” defense components, which would boost advanced manufacturing investments in India. With these events as the backdrop and the developing geopolitical situations across the world, India stands to benefit, resulting in an increase in manufacturing output.”

In any case, one thing is sure: India is certainly the country to watch in terms of 3D printing growth in coming years. How it will evolve is yet to be seen, but with the increased focus on metal AM adoption as well as work in dynamic sectors like defense, construction and healthcare, the country seems poised for a breakthrough before the decade is done.

NCAM puts on annual national conferences on 3D printing to showcase and advance AM in India

What do you think about the current state of 3D printing in India? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Imaginarium