Hoet on Redefining Eyewear With 3D Printing

The consumer goods industry stands out as one of the primary beneficiaries of additive manufacturing. Within this sector, a notable application involves crafting frames for eyewear, including both sunglasses and prescription glasses. In fact, according to a study published by SmarTech Analysis, the 3D printed glasses market is expected to reach a value of $3.4 billion by 2028. To delve deeper into the operations of companies within this industry, we interviewed one of its key players, bringing you an inside look at the market. Headquartered in Belgium, Hoet is a leading provider of 3D printed eyeglass frames. We sat down with its founder for an in-depth discussion of the company’s operations and to learn more about its activities.

3DN: Could you introduce yourself and tell us your relationship with additive manufacturing?

My name is Bieke Hoet, and I am the owner of Hoet, a Belgium-based design office offering freelance design services for the eyewear industry. I am also the founder of the iconic Hoet Couture and Cabrio eyewear collections. With a passion for innovation, we launched Hoet Couture and Cabrio eyewear in 2014. They are the industry’s first fully 3D printed eyewear collections.

Bieke Hoet

3DN: What is Hoet, and how did the idea of creating the company come about?

Hoet is a family-owned company with a long tradition in the eyewear industry. In fact, I am part of the sixth generation of my family to work in the eyewear industry. Our heritage dates back to 1885, where traces of Hoet retail optics can be found. In 1987, my father was the first Hoet to step out of the comfort zone of optical retail to start creating eyewear. At that time, I was still in school.

I was lucky to have young parents growing up. In 1997, when I finished my studies, I joined my father with the launch of the design office, offering eyewear design services to prestigious customers worldwide and meeting a high level of demand with unique expertise in the eyewear market.

3DN: When did Hoet start using additive manufacturing? What advantages does the technology offer for the company?

To stay at the forefront of your customers’ minds, you have to consistently surprise them, which can be achieved through innovation. An essential element of our design process is intensive research into materials and technologies. New technologies inspire us. We combine them with the old to create new products.

When I first looked at 3D printing technology for dental applications, I thought to myself, “If this is good enough to be used in your mouth, why not use this for the face?” Five years of intense research and investment resulted in the launch of Hoet Couture and Cabrio eyewear.

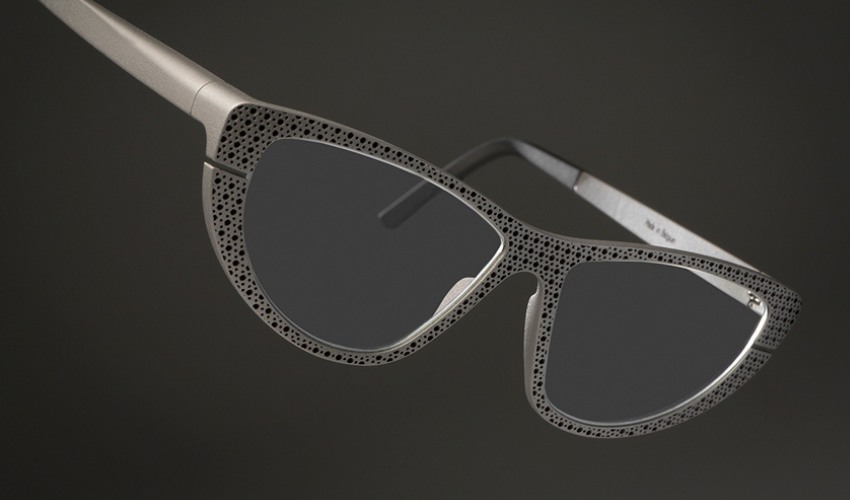

The “CABRIO eyewear” collection by Hoet.

3DN: Can you tell us more about Hoet’s 3D printed product line?

The Hoet Couture collection is manufactured in Belgium. The frame is made of surgical titanium, and the front has an open structure that varies from model to model. If you were to rely on only classic production techniques to make a similar frame, it would be almost impossible. For the greatest possible comfort, these glasses are available in various lenses and bridge sizes and are equipped with adjustable temples. We currently produce 17 Couture models, each available in various nose and lens size combinations.

3DN: Any last words for our readers?

To unlock new opportunities, break free from old habits, and choose differently! You can find more information about Hoet on the website, here.

3D printed Hoet eyewear frames

What do you think of Hoet and its use of additive manufacturing? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: Hoet