The Top Projects Combining AI and 3D Printing

When it comes to innovative technologies, artificial intelligence and 3D printing are always at the top of the list. Both of these so-called “disruptive” technologies have the potential to completely reinvent the way we manufacture in numerous industries. But what about when we combine them? We have seen a number of projects in recent years which have taken advantage of both AI and 3D printing for even more incredible parts including in the aerospace, medical and automotive sectors. Check out some of the most interesting in our latest listing to see how the combination of AI and additive manufacturing can result in innovative and exciting applications.

Lemki Robotix’s AI-integrated, 3D Printed Pain Relief

Back and neck pain are extremely common issues that many individuals face due to factors such as poor posture and uncomfortable seating, especially in recent years. The Ukrainian tech startup Lemki Robotix addresses these issues with a personalized back support product that uses a combination of 3D printing technology and artificial intelligence to create tailor-made solutions for each user. Through the use of a mobile application, users are prompted to take images of their body and posture. Artificial intelligence then processes these images, providing a detailed set of anatomical data that serves as the basis for designing the back support product, labeled Back Care. The support is then crafted to analyze the user’s anatomy and structure, ensuring optimal ergonomic design and comfort. It is also manufactured using recycled plastic materials, demonstrating a commitment to sustainability. Additionally, optional “Trigger Point Switches” allow for customizable levels of support and maximum pain relief, catering to the user’s specific needs. With its versatility, comfort-enhancing features, and customizable options, Back Care aims to alleviate the back pain and discomfort associated with poor posture or seating positions, offering users a unique and personalized solution for enhanced comfort and support.

Lemki Robotix’s 3D printed Back Care (Photo Credits: Back Care Kitckstarter Campaign)

The 3D Printed House Designed By AI

While 3D printed houses have become increasingly common, particularly throughout 2023, with numerous companies joining the trend, the integration of AI in their design process remains a groundbreaking development. Recognizing this opportunity for innovation, Litehaus has positioned itself as a pioneer in the field, leveraging AI technology to revolutionize the design and construction of 3D printed homes. Its first construction project will be located for Portela da Villa, Portugal and marks a historic milestone as the world’s first AI-designed, 3D printed house. While AI has previously assisted in the design of smaller 3D prints, this project represents an unprecedented fusion of technology, encompassing both interior and exterior design aspects of the residence. Additionally, this sustainable solution boasts a remarkable 70% faster construction time and a 20% cost reduction compared to traditional methods. Within a mere 20 hours, 45m2 of housing can be erected at an exceptionally low cost, highlighting the potential of this AI-integrated approach.

The design behind Litehaus’ 3D printed house in Portela da Villa, Portugal. (Photo Credits: Litehaus)

AI To Manage Material Reuse in Metal 3D Printing

A £600,000 research project funded by Innovate UK in the United Kingdom could ease the process of reusing metal materials in 3D printing. The project sees the Materials Processing Institute, Additive Manufacturing Solutions and AMFG collaborating to develop a predictive artificial intelligence-based material reuse management tool. Called SMART-APP, the tool will introduce intelligent predictive models for resource efficiency and waste reduction. If the research project is successful, SMART-APP will be made commercially available to users of LPBF 3D printing technology.The objective is to enhance the accessibility of metal 3D printing, a technology that, despite its immense potential, is perceived by some as cost-prohibitive due to issues such as powder waste and lengthy processing times.

Photo Credits: Materials Processing Institute

3D Printing Inspired by Jackson Pollock

Researchers at Harvard University have recently developed an innovative 3D printing technique, inspired by the artistic approach of the famous American painter Jackson Pollock. The method was devised by integrating artificial intelligence with fundamental principles of physics. Its primary aim was to emulate Jackson Pollock’s renowned paint-dripping technique within the realm of 3D printing. In traditional FDM 3D printing, maintaining close proximity between the nozzle and the printing plate is essential to ensure consistent material flow and prevent printing discrepancies. However, when liquids are projected from higher distances, they inherently become more susceptible to instability, often folding or curling upon themselves. Hence, the researchers aimed to enhance printing speed and precision, especially for intricate shapes, even when operating at greater distances from the printing plate. Artificial intelligence played a crucial role in this process, teaching the 3D printer’s nozzle how to control the flow of liquid at greater heights.

A Hydroelectric Dam in China

The integration of additive manufacturing in the construction sector has already led to significant reductions in labor requirements, reducing the drudgery and monotony of work. However, combining this technology with artificial intelligence amplifies its efficiency even further, as AI can oversee and control the machinery involved. And that’s what this next project in China is all about: a 180-meter-high hydroelectric dam to be erected by 3D printers and an artificial intelligence program, without human intervention. Should the project proceed as planned, the resulting structure will stand as the tallest ever constructed without direct human intervention. Set to be built on the Tibetan plateau, its design aims to serve as a pivotal source of electricity for the entirety of Henan province.

3D Printed Rocket Improvements With LEAP 71

Dubai’s tech firm LEAP 71 is seeking to bridge into a new era of rocket propulsion by implementing AI within their industrial 3D printers, aiming to manufacture highly efficient, cost-effective, and customizable rocket engines. LEAP 71’s fusion of AI and 3D printing promises not just faster engine development, but a paradigm shift in space exploration. Cheaper, more efficient engines mean wider access for both governments and private entities, unlocking new possibilities in satellite deployment and space missions. By leveraging their unique, AI-powered computational engineering model, the AI can seamlessly generate needed objects, which are precisely tailored for quick 3D printing and result in streamlined design and production processes. Through this integration of AI, the company is hoping to drive forward the frontier of space propulsion systems and usher in a new era of innovation within the aerospace industry.

(Photo Credits: Leap 71)

Using AI and 3D Printing to Design a Better Rocket Engine

Munich-based Hyperganic made waves back in 2020 when it revealed its prototype of a rocket engine made using both 3D printing and AI. Since then, the company, which is dedicated to accelerating innovation through AI-based engineering, has made significant progress. In 2022, it was announced that in partnership with AMCM, an EOS sister company, they were able to create what they claim was the world’s largest aerospike rocket engine standing at 80cm tall. Made using additive manufacturing and AI, the part was able to be significantly more complex thanks to the integration of AI-based software during the design process which allowed them to “obliterate the limits of what can be achieved with additive manufacturing.” This can be seen notably by the fact that they were able to design and then 3D print regenerative cooling channels directly into the manufactured part, making it a more contained and integrated solution to overheating.

The 80cm, copper aerospike rocket engine as seen during depowdering (left) and in its final form (right)(Photo Credits: AMCM)

AI and 3D Printing Collide in Czinger 21C

Another project in which the innovative technology of 3D printing merges with artificial intelligence is the Czinger 21C from US car manufacturer Czinger. Founded by Kevin and Lukas Czinger, a father-son duo, the company commenced production of this cutting-edge model in 2021. Within the production process of this flagship vehicle, AI plays a pivotal role in designing components prior to their 3D printing. Through sophisticated analysis, the AI assesses the potential G-forces applied to the car, employing simulations to determine the optimal size, shape, and weight of each part. This meticulous approach ensures efficient additive manufacturing of metal components using laser technology, thus minimizing metal wastage. Contrary to expectations, the Czinger 21C isn’t just a racing marvel, as it is also designed for everyday road use and is fully licensed for such in the USA. Dubbed the “hypercar of the 21st century,” it weighs in at under 1,500 kg and boasts a remarkable 950 hp engine, all thanks to the advancements of AI.

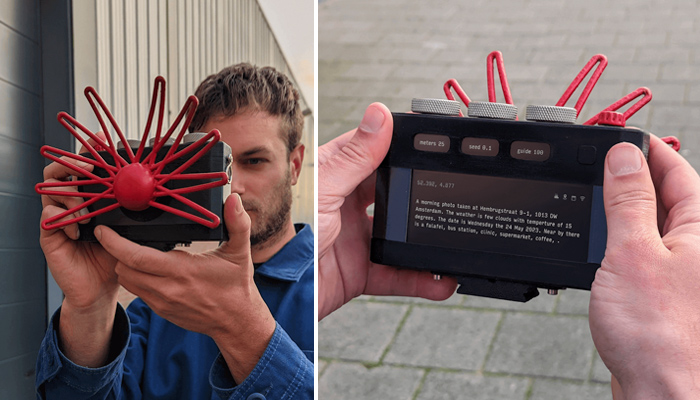

Paragraphica’s ‘Smart’ Camera

Another project that combines artificial intelligence with 3D printing is Paragraphica. Created by Danish artist and designer Bjørn Karmann, this camera integrates an AI algorithm capable of processing and displaying an image of a specific place and time. This information includes date, time, direction, weather conditions, temperature and even any point of interest. In addition, the entire camera structure has been 3D printed using FDM technology. Paragraphica also integrates a Raspberry Pi 4 Model B board connected to a 1.5-inch touch screen, which facilitates the control and visualization of the captured image. For those interested, the camera is available both as a physical prototype and as a virtual model for experimentation, accessible via the manufacturer’s website. Bring your images to life through these amazing technologies!

Which project caught your attention this week? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.