A 3D Printable Iron and Silicon Powder Could Be the Key to E-Mobility

Materials manufacturer Elkem Silicones has announced the development of a 3D printing powder for electric motor components. More specifically, the material is an iron silicon powder that can be easily magnetized and demagnetized, thus enabling the creation of more resistant parts. To test this new 3D printing material, the project partners have designed components for an electric scooter, a means of transport that is becoming increasingly accessible to the wider population. This initiative is part of the 3-year SOMA project (Lightweight solutions for e-mobility by AM for soft magnetic alloys), supported by EIT Raw Materials, funded by the European Union.

Traditionally, electric motor parts are manufactured by cutting sheets of metal. One of the limitations of this technique is the strength of the final part, which is often too fragile and not strong enough for its intended use. To overcome this problem, Elkem Silicones, in partnership with VTT (project coordinator), Siemens, Stellantis and Gemmate Technologies, turned to additive manufacturing to enable the production of higher-performance parts. The parties involved opted for a powder-based process.

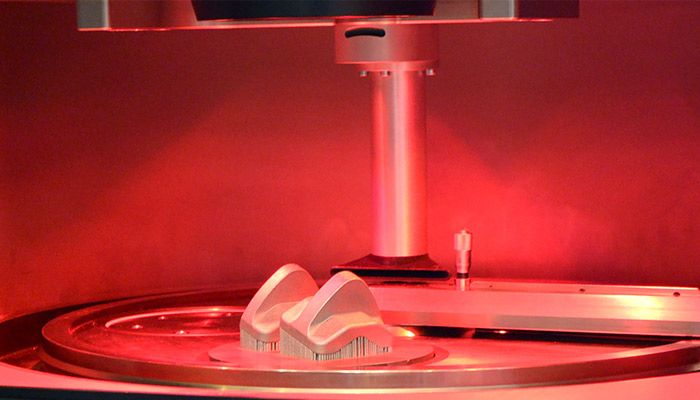

The SOMA project aims to use additive manufacturing to design parts for improved e-mobility (photo credits: SOMA).

Elkem Silicones has therefore developed a tailor-made material to meet the requirements of electric motors. The aim is to evaluate the performance of this powder by 3D printing test models. The company explains that the powder is based on silicon and iron. Silicon has high mechanical properties, is a semiconductor and is used in alloys with metals to increase their strength. As for iron, it is reputed to be highly ductile, malleable and magnetic. This combination of silicon and iron would provide interesting advantages for electric motor components, notably the fact that they can be magnetized and demagnetized quickly and easily.

ATV’s Tomi Lindroos explains: “This is a project with potential to transform motor parts manufacturing. We have successfully created a new [specialized] powder with good printability based on silicon-steel (with additives). 3D-printed components show enhanced ductility and competitive magnetic properties.”

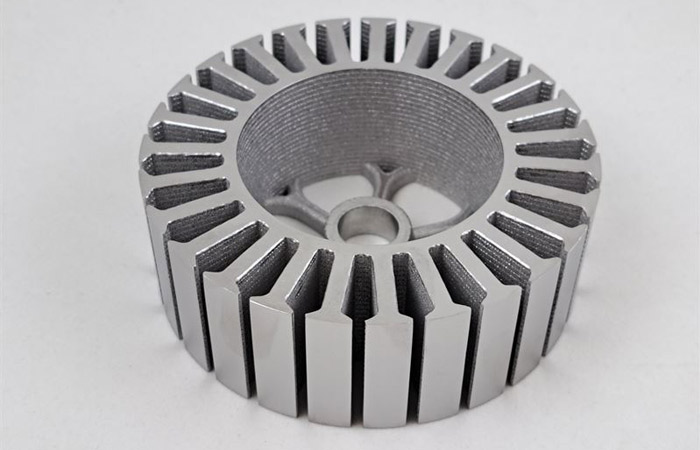

Example of a 3D-printed part made using the newly developed powder (photo credits: Elkem)

The partners aim to produce motor parts for an electric scooter. Jan Ove Odden, project manager at Elkem, concludes: “The powder developed in the SOMA project will now be introduced to the market by Elkem for evaluating the product for future commercial production. The product is currently available in small test volumes.” Find out more about the SOMA project HERE.

What do you think of this new 3D printing material for e-mobility? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.