A Closer Look at 3D Printing Materials: High Performance Polymers

Over the past few years, high performance thermoplastics have become a widely discussed topic in 3D printing with the market for them growing rapidly. These materials are attractive in the sector for their strength and lightness and there are a number of different ones available for use with additive manufacturing. For example, Polyaryletherketone (PAEK), a family of semi-crystalline plastics that can withstand high temperatures while maintaining tremendous strength. PAEK is primarily used in the form of polyether ether ketone (PEEK) and Polyetherketoneketone (PEKK), two materials that have high stiffness. A much lower cost alternative though, polyetherimide (PEI), also known as ULTEM, has also become increasingly widespread. But what exactly are high performance polymers? How do you print with them? Who are the manufacturers? Learn everything you need to know about these materials in the following guide on the PAEK and PEI families.

Production and Characteristics of High Performance Polymers

The first thing to note about high performance polymers is that though they of course share characteristics, they are not all exactly the same. That being said, in general it can be noted that high performance thermoplastics, and PEEK in particular, are as strong as steel and 80% lighter than metal, making them tremendously desirable in the production industry. Moreover, in addition to exceptional mechanical and thermal resistance of up to 250 °C (482 °F) for continuous operation, PAEK materials are also resistant to dissolving in oils and other substances unlike most other plastics. When exposed to fire, there are almost no gas or noxious fumes released.

And though they are more and more widespread in additive manufacturing, it is undeniable that their growth was slower than other polymers. Truth is, such materials have been around for over three decades, though they have been utilized through injection molding or machining. At first, Stratasys was the only company able to produce printers that could handle the high temperatures required to melt PAEK and PEI polymers. Nevertheless, as the market started opening more companies had the opportunity of experimenting with them, resulting in a mass commercialization of their inventions. As time goes by and the entry barriers are weakened, we see more and more companies entering the field and starting to produce printers capable of handling PAEK thermoplastics.

Another material, PEI was first developed by General Electric’s plastics department back in the late 1980s. In 2007 though, SABIC, one of Saudi Arabia’s largest public companies acquired the department and therefore the rights to the ULTEM brand. As the material is a more affordable alternative to PEEK, it immediately generated a lot of interest from a financial perspective. Combined with its various significant physical properties, such as high heat, solvent and flame resistance, dielectric strength and thermal conductivity, it made a great solution for engineering projects. Maybe most noticeably, ULTEM has become the go-to material when it comes to engineering applications with very demanding applications, such as in the aerospace industry.

3D Printing With High Performance Polymers

Generally speaking PAEK and PEI polymers are printed either using FDM (Fused Deposition Modeling) or SLS (Selective Laser Sintering). However, considering the high temperature capabilities of such polymers, it is understandable that no ordinary 3D printer can process those filaments. A PAEK/PEI 3D printer must have an extruder nozzle that can handle temperatures of over 300 °C (572 °F) as that is the melting point of such polymers. Moreover, the heated bed must reach at least 150 °C (302 °F) in order for the object to be taken off it. Finally, stronger cooling mechanisms are required to ensure the correct balance of temperature in the closed chamber.

Post-processing of high performance thermoplastics is necessary. As with every complex FDM printed part, support is needed. When it comes to PAEK and PEI though, due to the stiffness of the final object, removing the support can be challenging. As a result, a selection of tools is often used in order to finalize the part.

On the other hand, when it comes to SLS, the part is printed almost to perfection, without the need of extra tooling. However, producers do need to take into consideration warping. After the printing of an object is finished and the temperature in the chamber drops, the polymers tend to reduce in size. As a result, PAEK and PEI have been very popular when printing small objects, though the larger the part, the higher the warping effect. Although this can be controlled to an extent by optimizing key printing parameters such as speed and temperature, it remains a challenge.

That being said the use of high performance thermoplastics is not by any means perfected. There are still aspects of the manufacturing process that are being worked on and improved constantly. However, new innovations are improving this experience constantly. A number of companies are currently working on an FDM solution where the object’s support will be printed in a different material so that it can be removed quicker and easier once the printing has finished. Moreover, other organizations, like Kimya, have started focusing on offering combinations of materials in order to take advantage of the best of multiple materials. This way, the end product can be for example 70% PEEK and 30% carbon fiber.

Applications

As expected, a family of materials with such a number of significant features are useful in a variety of industries. Automotive quickly started utilizing the unique abilities of PAEK and PEI for a variety of applications. One of the areas where PAEK and PEI have been most disruptive is the production of low-cost rapid tooling for injection molding, thermoforming, jigs and fixtures. This allows companies to produce low to medium volume of parts at low cost without needing to invest in producing large quantities. Also, the production of customized parts is demanded increasingly as they can be altered to fit certain requirements and can get complex changes that enhance their structural build.

As with many other 3D printing materials, the PAEK and PEI families are widely used in the medical field. PEEK is famously used for the shielding of magnetic resonance imaging (MRI) devices. It is also considered an advanced biomaterial used for medical implants and in reinforcement rods and spinal fusion devices. The fact that it can withstand boiling water and super heated steam make it perfect for objects that need to be sterilised in extremely high temperatures.

High performance thermoplastics are also widely used in the aerospace industry. Chemical resistance, high strength-to-weight ration and low fire, smoke and toxicity ratings make such polymers the ideal substitute to metal that is often used for spacecraft parts and tooling. Thermal acoustic insulations, structural brackets, clamps and stand-offs, fasteners, connectors and tubing systems are just some of the examples where the aerospace engineering scene has started utilizing PAEK and PEI, often reducing the parts’ weight by 70%. Other industries disrupted by advanced thermoplastics include: marine, nuclear, oil & gas and many more.

Main Manufacturers and Price of the Materials

As one would expect, many of the big chemical companies have already realized the change coming in high performance thermoplastics in the additive manufacturing field. As a result, it is no surprise when names like Arkema, Lehmann & Voss and Solvay (just to mention a few) are brought up when it comes to producing PAEK materials. However, when it comes to PEI, the ULTEM brand –from SABIC- is the only available one in the market for now.

In terms of printers that can support PAEK and PEI, the Chinese manufacturer, INTAMSYS, has gotten a lot of attention, as they offer a range of professional and desktop 3D printers that are suited for high performance polymers. Nevertheless, the Dutch Tractus3D is becoming more and more popular as well as the German giant, EOS, that recently released a new HTLS (High temperature laser sintering) printer that can handle such materials.

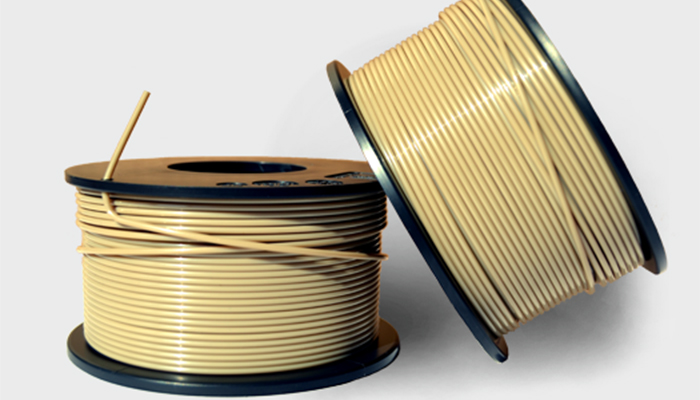

That being said, as you can expect, these high-performance polymers do not come cheap. PEEK, UTLEM and PEKK are some of the most expensive 3D printing materials available on the market. Though ULTEM is a slightly cheaper alternative, a 1 kg spool of the filament will start at over $200 and often costs much more depending on brand and the properties of the material. PEEK meanwhile will often cost over $300 and up to over $700 for 1 kg of the material with PEKK averaging between $400 and $500 for the same amount.

Not only that, but if you are interested in filament, you must also keep in mind the fact that printing cannot be done by any printer. You need to invest in one that has been designed with high-performance polymers in mind, as mentioned above. These printers understandably are also more expensive than a low-cost FDM model. Indeed, many will start over $5000 and most are much more. Still, over the years we have seen that as the market grows, so do the choices available to consumers. Perhaps in the near future, we will see these prices drop both for printers and materials as applications with high-performance polymers become even more widespread in additive manufacturing.

What do you think of the use of high performance thermoplastic polymers in 3D printing? Can you see other industries being disrupted in the near future? Let us know what you think about this article in a comment below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!

*Cover Photo Credits: ApiumTec