3D Printing in Nonprofits: Innovating Aid with AM

There are almost 10 million nonprofit organizations around the world today. In the United States alone, there are 1.5 million registered 501(c)(3) organizations that operate with goals oriented toward altruistic or humanitarian causes. Spanning from small, grassroots community groups, to large, multinational programs with operations around the world, nonprofit organizations can take many forms and perform a variety of roles based on the needs of their surroundings. Their sectors are vast as well encompasing everything from advocacy to food security, medical assistance, and law, even within the world of additive manufacturing in construction, where 3D printing is being used to create homes and schools thanks to nonprofit organizations.

Indeed, these groups play a big role in many communities around the world and have been instrumental in ways that governments and for-profit entities have not been effective. However nonprofit organizations, as their name and nature imply, are often operating on very tight budgets with small teams of dedicated people and volunteers. A 2022 report from Fitch Ratings found that nonprofit healthcare organizations had an operating margin of just 0.2%. This slim balance means that organizations are often hard-pressed to find the resources necessary to complete their tasks. Enter 3D printing, where a wide range of technologies and industries bring the benefits of lower cost, fewer staff and training, and the ability to create on-demand rather than operating in constant shortage and excess. Not to mention the elimination of logistics and supply chain barriers, and the lower operating costs in both materials and energy.

3D printing has been providing innovative solutions that increase productivity and decrease costs.

3D printing technology has the potential to revolutionize the nonprofit industry in ways that provide cost-effective and quality solutions, increasing the effectiveness and capacity of nonprofits in the process. We can already see 3D printing-based nonprofits emerge across several industries, and it is from these professionals that we can learn about the real impact of 3D printing in nonprofits, the benefits it brings, areas for improvement, as well as their expert opinions on the future of 3D printing technology in the nonprofit field. Throughout this article, we will explore the various applications of 3D printing in nonprofits and gain insight from the professionals who use them to gain a better understanding of the potential that 3D printing has as a means to enhance humanitarian efforts around the world.

Nonprofits Provide Accessible 3D Printed Prosthetics

So how exactly are we already seeing the use of AM in nonprofits? Well, one of the earliest and most enduring forms of 3D printing in nonprofit success is in the area of accessible prosthetics. According to a 2022 market report, traditionally manufactured prosthetics can cost between $1,500 and $8,000 out of pocket, whereas a 3D printed prosthetic that fulfills the same role can cost as little as $50. This, coupled with the advances in 3D printing with high-performance polymers means that 3D printed prosthetics can be more durable and long-lasting for just a fraction of the cost.

Following the early success of the Robohand project, one of the first programs that saw future e-NABLE founders partner with 3D printer manufacturer MakerBot to develop and share 3D printed prosthetic models, many doors were opened and began to reveal how 3D printing could be used to make a difference. Especially key here is accessibility. 3D printing’s capabilities for local production have made a true difference especially in areas with less access to steady medicine, such as war zones.

Today, nonprofit organizations based around 3D-printed prosthetics make up an enormous portion of nonprofits that use 3D printing. From conflict zones like Ukraine where nonprofits use 3D printing to aid soldiers and victims of conflict, to local community assistance in the United States and beyond. With the reduced cost of 3D printing and freedom of design, customization, and materials used, prosthetics quickly became a spotlight for additive manufacturing in nonprofit work.

For Orlando-based nonprofit Limbitless Solutions, Executive Director Dr. Albert Manero explains, “3D printing is a valuable tool for prototyping design ideas quickly which accelerates project development. […] 3D printed parts when optimized have been able to perform at a high level.” Showing that 3D printing can match or exceed its traditionally manufactured counterparts, and that even within nonprofits, the trends of the AM market influence production. Dr. Manero continues, “Limbitless Solutions has been using 3D printing as a tool in our design process since day 1. We are using this for not only final parts, but also for molding prototyping and as a positive die for thermo-vacuum forming.”

3D printed prosthetics can help provide children with more accessibility at a fraction of the cost. (Photo credits: Limbitless Solutions)

Simplifying and Streamlining with 3D Printing

Of course, prosthetics are only one part of the puzzle of 3D printing and nonprofits. With the continued evolution of 3D printing technology, we have seen the opportunities for its expansion balloon across the world as organizations take advantage of prototyping and breakthrough design solutions. The solutions can find their application in several diverse areas, from meeting demand for prosthetics and 3D printed medical equipment in warzones, to process streamlining and simplification, with the end goal of enabling the complete 3D printing of prosthetics from the comfort of your home, as is the case with research done at Loughborough University. Apart from prosthetics, 3D printing nonprofit organizations have also been actively utilizing the technology to manufacture various medical pieces including pediatric hearing aids (3DP4ME), first aid equipment, as well as prototyping for educational and medical research purposes.

The benefits extend beyond a single product, with the online, often free or open-source nature of many 3D printing and maker designs means that files can be printed on-demand virtually anywhere in the world. Such is the case with several organizations including Glia, which utilizes open-source designs that can be accessed, modified, and improved without incurring extra costs or access barriers. Although technically not a nonprofit, Glia operates similarly and fulfills many of the same criteria while working in the same field as nonprofits, therefore we want to share their valuable insights along with the others.

The team from Glia told us that “The accessibility and affordability of desktop 3D printers and filament make them portable and energy efficient. […] 3D printing provides the unique ability to swiftly pivot between different products, or multiple items can be printed simultaneously, addressing specific or urgent needs. The concept of printing on demand eliminates the need for mass production and inventory storage (and associated costs), streamlining the production process and facilitating a rapid response with shorter turnaround times.” And it is not only the production side of 3D printing that is more efficient but also the human side as well.

Field Ready has made use of 3D printing in areas around the world, such as in the South Pacific. (Photo credits: Field Ready)

As they explain, “Operating a 3D printer requires minimal training, making it an ideal technology for incorporation in various environments. This ease of use enhances the adaptability of 3D printing technology within nonprofit organizations, enabling them to leverage its benefits without extensive training requirements.”

While it may still yet be unattainable to reach the large-volume production levels seen in industrial additive manufacturing, 3D printing has illustrated its effectiveness and convenience at working in the field, a fact further confirmed by Dr. Eric James of Field Ready; “3D printing is an incredibly versatile and flexible tool that works well where there is complexity and only a small number of items are needed. The relatively low cost and ease of use has made [it] a transformational tool.”

3D Printing Helps Nonprofits Help Others

Field Ready is yet another nonprofit organization that uses the technology to build prototypes and small-batch 3D prints from disaster areas. With a wide repertoire of 3D printed items to suit the needs of the communities they serve from 3D printed medical and sanitation stations to toys and 3D printing business ventures. Like 3D printed prosthetics, parts produced via 3D printing represent a significant advantage over traditional materials in terms of cost, availability, and operation, while also promising high quality and durability.

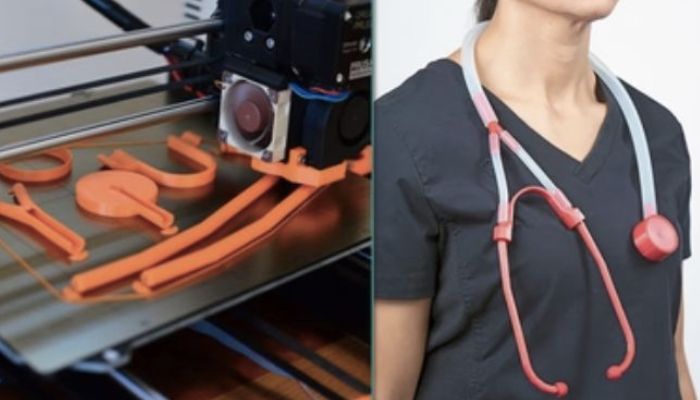

Glia too, provides innovative solutions in the form of 3D printed tourniquets and stethoscope parts. Here they noted interesting results, “[We have] purposefully adopted a self-assembly model for our stethoscope. Over time, we’ve observed that individuals who actively participate in the assembly process, such as putting together their very own stethoscope, develop a more intimate connection with their device. While there may be initial skepticism by many, thinking that a kit of 3D printed plastic parts would yield an inferior product, users frequently [realize] that plastic components and affordable prices do not necessitate a compromise in quality.”

Components for a 3D printed stethoscope (Photo credits: Glia)

The role of 3D printing in nonprofits takes on an additional aspect that best reflects the humanitarian nature of the organizations that utilize it. In a previous interview with 3Dnatives, Executive Director of Field Ready, Dr. Eric James stated his organization’s goals of “humanitarian making”, which involves fostering an environment of individuals and organizations who seek to improve local manufacturing, response, resilience, inclusiveness, and community.

The task of building up professionals and organizations who are well-versed in 3D printing and can suit the needs of nonprofit work can be a difficult task, but expanding awareness of the technology is key to its continued use. As Dr. James explains, “There remains relatively little knowledge about 3D printing. Most people who are not involved in making/fabrication do not know about the capabilities and utility of this technology. We try to educate people and communicate that this is a useful tool in the contexts in which we provide aid.”

The aspect of cooperation and collaboration is one of the aces that nonprofits have up their sleeve. Organizations that band together to share information or resources often have the benefit of reach, experience, and a deeper expert knowledge of the technology, people, and environment. While many examples exist of non-3D printing-related nonprofit networks, it is exciting to see the same possibilities begin to take shape with 3D printing. “Openness fosters international collaboration,” Explains the Glia team, “sharing knowledge and fostering collaboration represents a noteworthy achievement in the dynamic intersection of 3D printing, open-source initiatives, and nonprofit endeavors.”

Hurdles to Overcome

While the future may hold many exciting things in store for AM and its use in the nonprofit field, there are still certain barriers that are being addressed which, once cleared, may speed the adoption and advancement of the technology around the world. The most important aspect to keep in mind is that the use of 3D printing in nonprofits is still quite new and requires more time and awareness to fully develop.

As Dr. James points out, “While there is a technical issue with 3D printing simply not being ubiquitous or as easy to use as some had predicted, there are also institutional barriers. There is a bias toward centralized supply chains which presents a significant challenge to localization.” This presents the greatest issues to remote deployments where access to further resources may be hard to come by. Training and the proliferation of information can help in this regard, but it requires more time to reach the level of acceptance enjoyed by traditional methods of production.

The Glia team shares a similar plight, as they seek to overcome the stigma of plastic components in the context of environmental sustainability, “One of the most significant challenges that we encounter – the prevailing stigma surrounding plastics – as it’s often perceived as cheap and disposable. Overcoming this misconception is crucial, as it hinders the acceptance of 3D-printed medical devices. While acknowledging the environmental concerns related to single-use plastics, we emphasize that plastics, when used responsibly, can contribute to positive outcomes. Clinical testing demonstrates the performance of 3D-printed products, while physical testing underscores their quality and durability. Through these efforts, we actively engage in public education promoting a “good vs. evil” use of plastics model, aiming to shift perceptions and garner acceptance within the community, ultimately dispelling the notion of plastics as inherently negative and disposable.” Again, this is an area where those within the 3D printing industry have more knowledge about the environmental impact of various polymers, filaments and other 3D printing materials.

Awareness, training, and education are important steps toward building networks of 3D printing in communities around the world. (Photo credits: Field Ready)

Ultimately, the role of education and raising awareness will do the most good for extolling the use of 3D printing in the nonprofit industry and building up international consensus. Even within Field Ready’s ‘humanitarian making’ efforts, Dr. James explains the task, “Field Ready is a pioneer in this area and has worked hard to bring groups and interests together. A number of our initiatives have contributed to wider efforts while we strive to be a good partner to others. One of the challenges is that humanitarian making represents a real hybrid area which has not reached is full potential. Each partnership is part of a wider effort move this transformational approach toward mainstream use.” Despite challenges though, he remains upbeat, concluding, “Improvements are showing the potential coming through as the years have progressed.”

The Glia team also shares a positive outlook toward the future of the industry, “we’ve witnessed a growing interest from others exploring our business model and seeking to replicate it in different locations around the world. […] a grassroots movement is spreading the word about our vision, mission, and the quality and potential of well-designed and implemented 3D printed products. This evolving perspective is leading to increased acceptance of this production method over traditional approaches.”

Looking to the Future of Nonprofit 3D Printing

The future of additive manufacturing is already promising to have some exciting breakthroughs in store across the industries, including medical, materials, and microscopic construction. However, the innovation across the industry as a whole is also reflected within the nonprofits that use these 3D printing technologies. One of the most frequent responses we received is about the growth of the 3D printing nonprofit field as a whole; with new developments enlarging the operational capacities of existing organizations while enabling professionals in the field to further their technical skills. “Quality and consistency are two factors of priority,” remarks Dr. Manero.

The team from Glia meanwhile states their goals for future growth, “We are committed to leveraging our expertise to broaden our humanitarian impact, particularly by advancing internally from basic to more advanced medical devices. This progression represents a significant milestone, as it facilitates the accessibility of complex diagnostic and treatment equipment in low- to middle-income regions globally.”

Quality and consistency will remain drivers that push the services that 3D printing nonprofits provide. (Photo credits: Limbitless Solutions)

One further interesting factor to consider when utilizing 3D printing technology in nonprofit organizations is the ability to service and make repairs privately without the need to call for company technicians and licensed products, otherwise known as the ‘Right to Repair’. It is a concept that has been debated over between manufacturers and their customers across the world of technology, 3D printing included. While the proposal is up for debate in governments around the world, it is undeniable that the right would be invaluable to nonprofits that operate on slim budgets.

Glia explains their interest in the issue, “This [Right to Repair] movement prioritizes repair over replacement, aiming to enhance the affordability of repairs, leading to a more sustainable economy and waste reduction. Glia is actively participating in a project aligned with this movement, focusing on restoring inoperable and obsolete medical equipment for which replacement components are simply unavailable. […] Locally designed and manufactured replacement components, often utilizing 3D design software and 3D printers, breathe new life into crucial equipment in regions where easy access to such resources is a luxury. This trend extends beyond healthcare, showcasing the potential for 3D printing to play a vital role in various sectors within lower-income regions worldwide serviced by nonprofit organizations.”

With the trajectory of the additive manufacturing industry as a whole, there is an air of optimism about the use of 3D printing as a power for good to help deal with some of the most pressing needs that people face in their day-to-day lives. We can already see the efficacy that comes with 3D printing with a mission and thanks to pioneering organizations, we can envision a day where 3D printing enables people around the world to access the help they need, when it is needed.

As additive manufacturing technology advances, so do the potential uses for 3D printing in nonprofits.

For more information about the various organizations listed in the article, feel free to visit their websites to learn more about their operations, donations, and the technology they use. What do you think about the role of 3D printing in humanitarian work? How do you see the industry changing in the coming years? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover photo credits: Field Ready