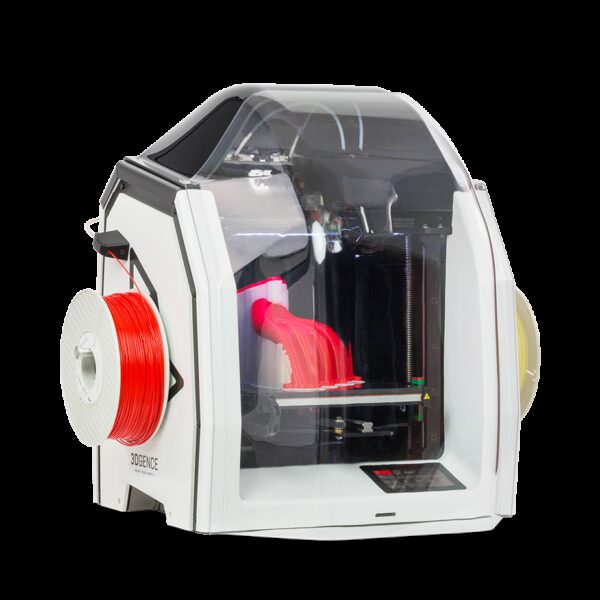

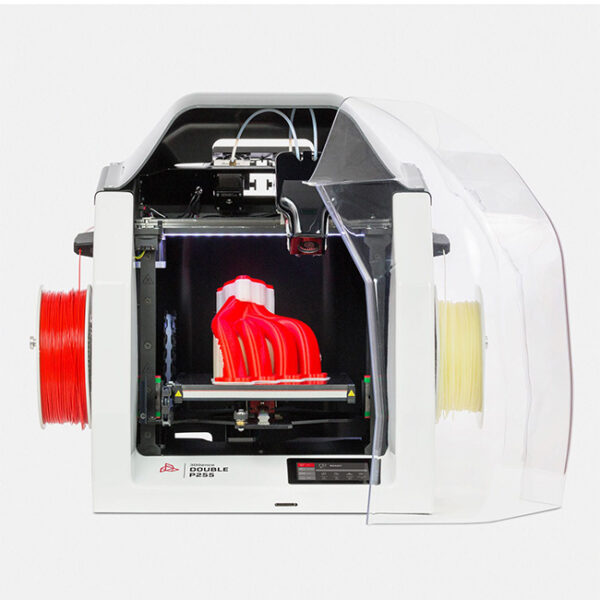

The 3DGence DOUBLE P255, is a 3D printer developed by the Polish manufacturer 3DGence, and it is the brand’s excursion into the world of dual extrusion 3D printers. It is part of the brand’s extensive range of printers among which are the 3DGence ONE and the Industry F340. 3DGence is a company that has grown exponentially since its inception in 2014. Its dual extrusion 3D printer allows the user to print with different materials at the same time, including soluble ones that serve as supports.

DOUBLE P255, Using Two Printing Materials at the Same Time

The DOUBLE P255 3D printer, based on FFF extrusion technology, has a print volume of 190 × 255 × 195 mm and has a layer resolution of up to 20 microns. Like all of the manufacturer’s machines, it is possible to change extrusion heads depending on the application. This compactly designed machine features a closed printing chamber and a manufacturing tray capable of self-calibration. The DOUBLE P255 3D printer is compatible with a number of 3D printing materials for example flexible materials, PET, PLA, PP, and ABS. It is also capable of working with soluble materials, such as HPS or BVOH, which gives a great advantage when used as support material in models with complex geometries. It is enough to submerge the parts in water to eliminate these soluble supports and obtain the final model.

There are a number of other notable features of the DOUBLE P255 3D printer besides double extrusion. The 3DGence solution features, for example, a touch screen which can be used for greater congrol and connectivity via USB cable or SD card. Weighing in at 32 kilograms, the DOUBLE P255 is compatible with 3DGence SLICER 4.0 lamination software, where you can optimize and prepare models for subsequent 3D printing. Without a doubt, this desktop solution is ideal for creating complex parts with multiple materials.