Polymer 3D Printing Is Being Driven by Material and Technological Innovations

The first 3D printing process invented was stereolithography, a method wherein a photosensitive polymer is hardened via a laser, putting plastics at the forefront of the market since the very beginning. Something that has continued to this day. Indeed, according to a a study by IDTechEx, titled “Polymer Additive Manufacturing 2023-2033: Technology and Market Outlook,” polymer 3D printing is valued at $21 billion in 2033. And to understand this growth, it’s not enough to say that polymers have always been a part of 3D printing, but to look at what innovations have been dreamed up in recent years. More and more players are offering other forms of materials such as foams, composites or viscous thermosets. The same applies to new printing technologies – volumetric 3D printing comes to mind. But what is driving the growth of the plastics printing market? And what are the remaining obstacles?

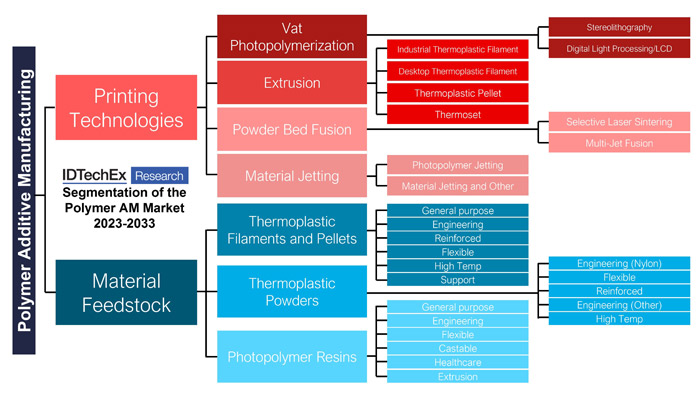

The IDTechEx report begins with a segmentation of the polymer additive manufacturing market by technology and material – as you can see from the diagram below, there are many printing processes, thus multiplying the material offerings. Filament, resin, powder, pellet: it is interesting to note that polymer powders are expected to grow rapidly over the analysis period. This increase could be attributed to the properties that these plastics offer – they are most often so-called technical polymers that are mainly used for industrial applications. Indeed, the report emphasizes that users are more focused on final production, to the detriment of rapid prototyping. Furthermore, these users have a better knowledge of the technologies, which allows them to move towards high value-added applications such as the manufacture of custom-made parts, in more or less large volumes. However, rapid prototyping remains a key use of polymer 3D printing.

Photo Credits: IDTechEx

Technological Innovations

What is interesting in the study proposed by the firm is to note the place that startups are taking in this market: while historical players such as 3D Systems or Stratasys continue their innovation strategy, initiatives are emerging around new materials or faster or more efficient printing processes. The objective of these startups is to push the potential of polymer additive manufacturing, by improving each link of the value chain – software, machines, materials, post-processing, etc. The study has identified “innovators” in these different segments – nine to be precise – and shows how the market could benefit from these advances to grow. These are obviously projections, and it will be interesting to see in the next few years how these startups have really influenced polymer additive manufacturing.

One of these startups is Evolve Additive Solutions which has developed a process called STEP for Selective Electrophotographic Thermoplastic Process. It has 3 steps: imaging, alignment and fusion. For the first step, the machine uses a 2D electrophotographic imaging engine. In fact, the startup has combined some of the characteristics of sheet lamination, 3D printing and powder bed fusion, allowing it to achieve a significant manufacturing speed, competing with injection molding rates. Of course, a technology that offers higher volumes quickly will interest the market. Staying with technologies, the report highlights startups like Readily3D or Xolo that rely on a volumetric printing method. Instead of designing a part layer by layer, it is created in a single step. This circumvents the challenges of printing speed – especially on resin processes – while maintaining a high level of detail.

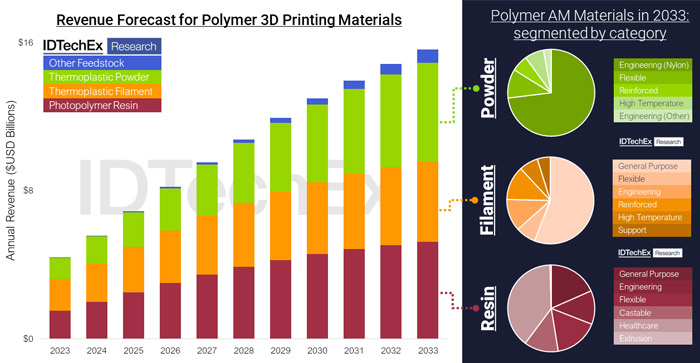

Market revenue by material category (photo credits: IDTechEx)

Polymer 3D Printing Market Driven by Materials

The study focuses specifically on polymer materials in the market, stating that their revenues will far exceed those of hardware. In fact, the materials will be worth $15 billion by 2033. In this niche, the objective is to meet the challenges of performance but also sustainability: the environmental aspect of polymers developed is now a key issue. It is therefore not surprising to see an increase in recycled and recyclable filaments, often made from reclaimed plastic waste.

Another important aspect is the performance side: what are the characteristics of a material that can be combined? What are the needs of manufacturers today and how to meet their demands? One of the examples given in the report is that of the startup Tiamet3D, which has developed a composite based on PLA and nano-diamonds. The objective is to provide a resistant and accessible material for the market users. There are, of course, many other examples, with manufacturers offering better materials – flame resistant, with ESD properties, etc. One thing is for sure, the polymer 3D printing market has a very bright future ahead of it! If you’d like to learn more, read the full study HERE.

Are polymers the future of additive manufacturing? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Sinterit