Medical 3D Printing Expands in the American Midwest

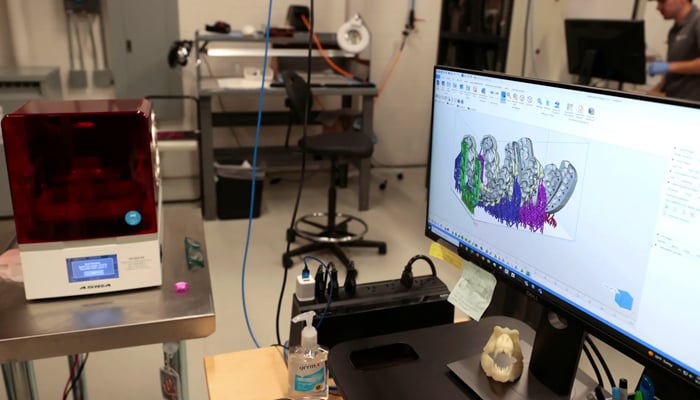

With a population of less than ten thousand, the small town of Plymouth, Michigan is part of the Midwest region that is pioneering the application of 3D printing in medicine. This past summer, additive manufacturing company Materialise expanded its North American offices in Plymouth by more than 16,000 square feet and incorporated 3D printers capable of making objects out of titanium powder. Materialise, which is headquartered in Belgium, has a 3D printing service that provides them with different types of printers, either polymer or metal, which they use to develop 3D printed medical models. After the scientific advances that the company has managed to develop in recent years, the company’s name has been able to grow as quickly as the new Materialise North American headquarters.

From developing a polymer-based dental plate whose main function is to align a person’s teeth, to 3D printing titanium plates to help heal broken bones. Materialise has made thousands of models for implants, surgeries or prototypes formed via scans and MRIs. What’s more, through the use of 3D printed surgical cutting aids to show doctors exactly where to make cuts to reduce surgery times, assist with mobility and posture correction, and speed up patients’ recovery time thanks to their accurate implants, Materialise and companies like it are helping to save lives and revolutionize healthcare.

Medical 3D printed components can be personalized and edited prior to printing.

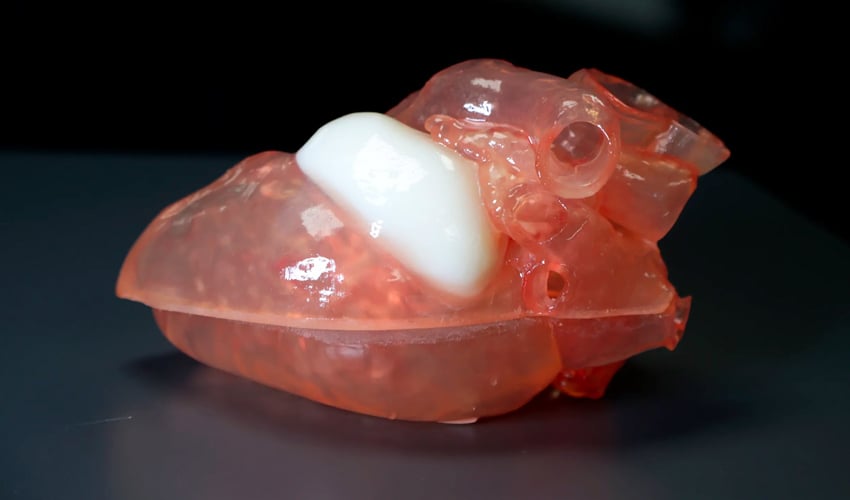

Reports often display information or new technologies about how companies are revolutionizing 3D printing, however within the medical field there are often tangible results from patients who directly benefit from the sometimes life-saving advances that 3D printed medical components supply. Bryan Crutchfield, vice president and general manager for Materialise North America highlights his own stand-out story from a recent cooperative project between Materialise and Cincinnati Children’s Hospital to model and remove a heart tumor from a pediatric patient. “The young man’s name was Brad,” Explains Crutchfield, “and he had a tumor for seven or eight years that they were monitoring. When he turned 16, they thought, ‘OK, the tumor is invasive enough. He’s old enough. We need to go in and take it out.’ We helped them by creating this pliable model.”

Thanks to 3D modeling, the doctors were able to prepare with a far greater chance of a successful operation than without this technology. Crutchfield continues, “What they discovered through the model was that once they removed the tumor, there would not be enough tissue left to reconstruct his heart. So, in his case, they didn’t crack his chest open and surgically remove it. What they did instead was they went in minimally invasively and they did a thermal ablation.” In addition to the main function of 3D printed medical models, which is to find the most efficient, least invasive methods to cure the patient, they also serve to better explain the procedure to the family, or so that medical students can view organs in perspective, without having to visualize them in a book or on a computer. Gradually, with the development of these models and prototypes, the next generation of doctors and surgeons will be able to operate more accurately thanks to 3D modeling and printing technology.

Post-processing is a crucial step in all 3D printed objects, and even more critical when for medical use.

What do you think of Materialise North America expanding its operations? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: Eric Seals, Detroit Free Press