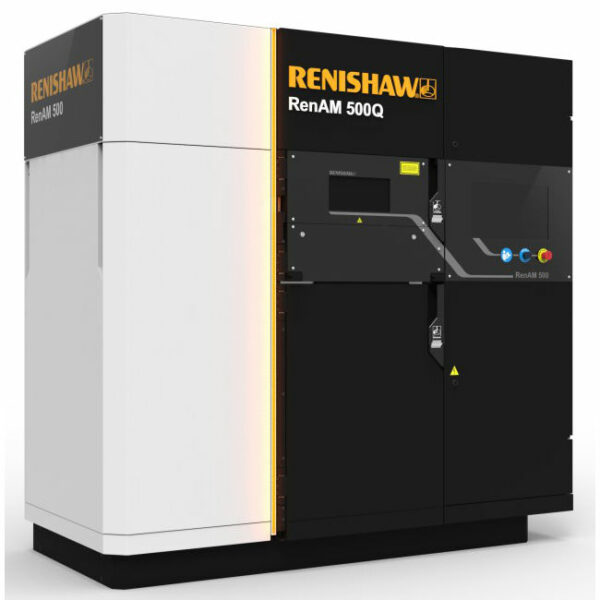

Renishaw, a leading British technology solutions manufacturer, entered the metal additive manufacturing market back in 2011. Since then, it has quickly made a name for itself with its solutions, all using metal powder bed fusion technology. One of its most popular offerings is the RenAM 500Q 3D printer, launched in 2017 and the direct sister offering to the RenAM 500S.

The solution is offered in two types, the original or Flex. As the name suggests the RenAM 500Q Flex allows for additional flexibility, in particular when changing power. This is in contrast to the more general model wherein powder removal is automatic. Renishaw notes that this means, “[Users] can quickly change powders in-house, to meet demand, and parameters and material properties transfer seamlessly between systems thanks to the common build environment.”

Features of the RenAM 500Q

RenAM 500Q is Renishaw’s multi-laser additive manufacturing system and one of its flagship machines among the RenAM 500 line. It differs from other offerings from the company due to its four 500 W lasers, each able to access the whole powder bed surface simultaneously. Thanks to this, the RenAM 500Q is able to achieve significantly faster build rates, improving productivity and lowering cost per part. Furthermore, the printer features automated powder and waste handling systems that enable consistent process quality, reduce operator intervention time and ensure high standards of system safety.

With a speed of up to 150 cm3/hr, the RenAM 500Q can quickly create complex metal parts. In addition, its large build volume of 250 mm x 250 mm x 350 mm means large parts can be created. Not only that, but it also has a number of other features that are present in all the RenAM 500 line. Namely, Renishaw points to the gas flow system, precision dynamic control and software for connected digital workflows. All these characteristics have been designed to allow for better production, with industrial applications especially in mind when printing with the RenAM 500Q.