All You Need to Know About Resin 3D Printing

Resin 3D printing, also known as vat photopolymerization, is one of the most popular families of 3D printing technologies. It offers precise, detailed and high-quality results, making it a popular choice in many industrial sectors, such as jewelry, dentistry and rapid prototyping. In this article, we’ll explore in detail how resin 3D printing works and its applications.

Resin 3D Printing Basics

Resin 3D printing uses a type of liquid called photosensitive resin, which solidifies when exposed to UV radiation. This technology falls into three main categories: SLA, DLP and MSLA, which are distinguished by the light source used and the method of shaping this light.

- SLA (Stereolithography): SLA was introduced and patented in 1986 by Chuck Hull/3D Systems. This technology uses a laser directed by a galvanometer, which is a movable mirror, allowing the laser to be moved along the X and Y axes. The laser solidifies the photosensitive resin, layer by layer, to create the desired object.

Formlabs’ Form 3L is a resin printer that uses the SLA printing process. Check out our test!

- DLP (Digital Light Processing): DLP was created and patented by Texas Instruments for projectors. DLP 3D printers use a projector to project UV light onto the resin tank. The UV light is redirected by small mirrors to turn each pixel on or off, enabling selective polymerization of the resin.

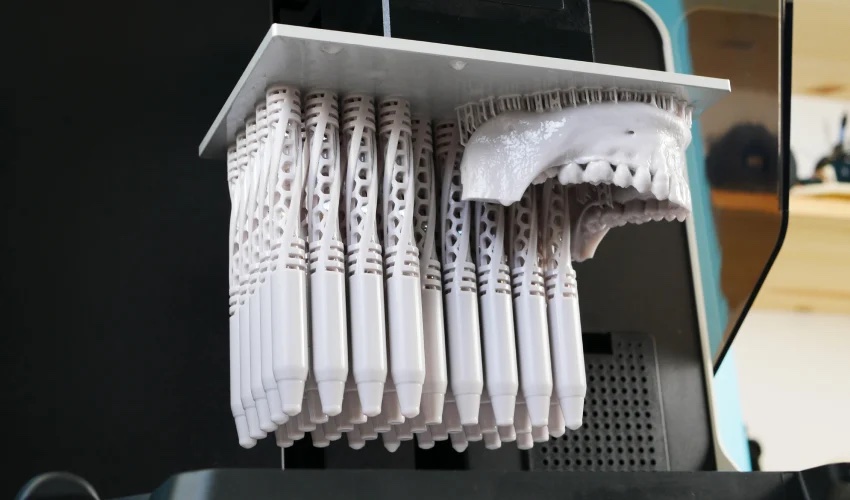

DLP allows you to create serial objects much faster than SLA. Learn more about the capabilities of these technologies (photo credits: EnvisionTec)

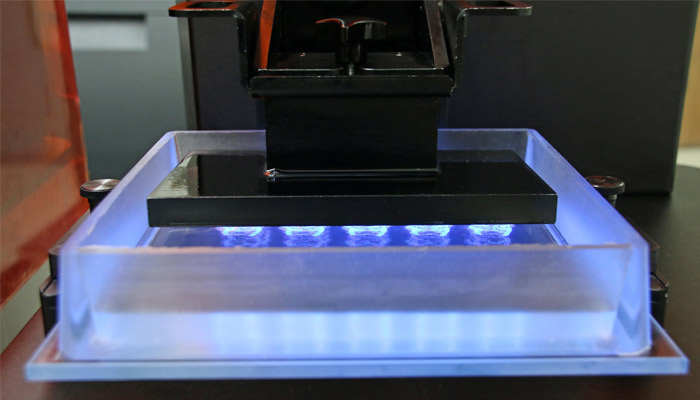

- MSLA (Masked Stereolithography Apparatuses): MSLA uses an LCD screen to mask the UV light source. By switching each pixel on and off, the LCD screen acts as a stencil capable of creating 2D shapes to allow the UV light to pass through and cure the resin.

MSLA 3D printing is becoming increasingly popular, helping to reduce the entry cost of resin printing while offering precision and high quality. Find out how it differs from SLA printing.

All three methods share a similar architecture, consisting of:

- A resin tank (called a vat);

- A printing plate moves along the Z axis;

Technological Variants

Although the three main resin technologies are SLA, DLP and MSLA, some manufacturers are looking to improve these technologies for optimum performance. For example, Formlabs has developed a type of SLA called LFS (Low Force Stereolithography), which aims to improve printing precision. Carbon has developed DLS (Digital Light Synthesis), an evolution of DLP designed to deliver faster printing speeds. BCN3D has patented VLM (Viscous Lithography Manufacturing) technology, which uses MSLA as its base, offering advanced functionalities such as multi-material printing.

Post-Processing

After resin 3D printing, all resin technologies require similar post-process steps. The printed part must be cleaned to remove excess uncured resin. It must then be post-polymerized, as polymerization during printing is only partial. Special post-processing machines are available to facilitate the washing and curing of resin prints.

Cleaning and curing machines automate the post-processing process and deliver more uniform results.

The Resin 3D Printing Market

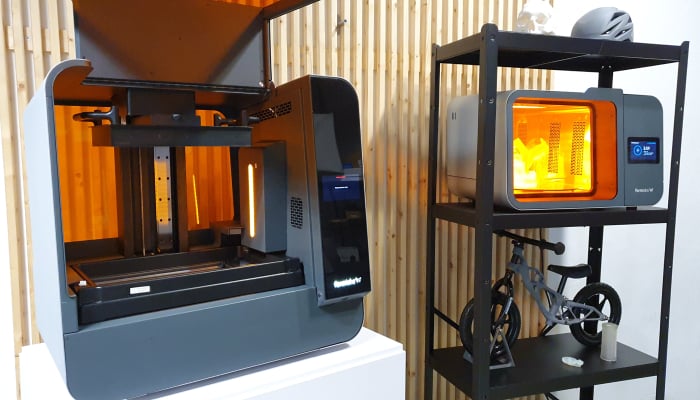

With the different resin technologies available, the resin 3D printing market is vast and diverse. There are machines to suit different needs, from small affordable office machines to large industrial SLA printers. Resin 3D printers offer fine applications thanks to their precision and high reproduction of detail. They are used in many sectors, such as jewelry, dentistry, the medical industry, aerospace and automotive.

3D resin printing can be used to produce parts of any size with high precision

Conclusion

Resin 3D printing is a technology that enables the additive manufacture of precise, detailed parts. Thanks to its different technological variations (SLA, DLP and MSLA) and the advances made by manufacturers, this technology offers infinite possibilities in many fields. Whether for prototyping, the production of functional parts or artistic creation, 3D resin printing has become an essential tool for many professionals looking for a precise tool capable of producing high-quality parts.

What do you think of resin 3D printing? Do you use it? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.