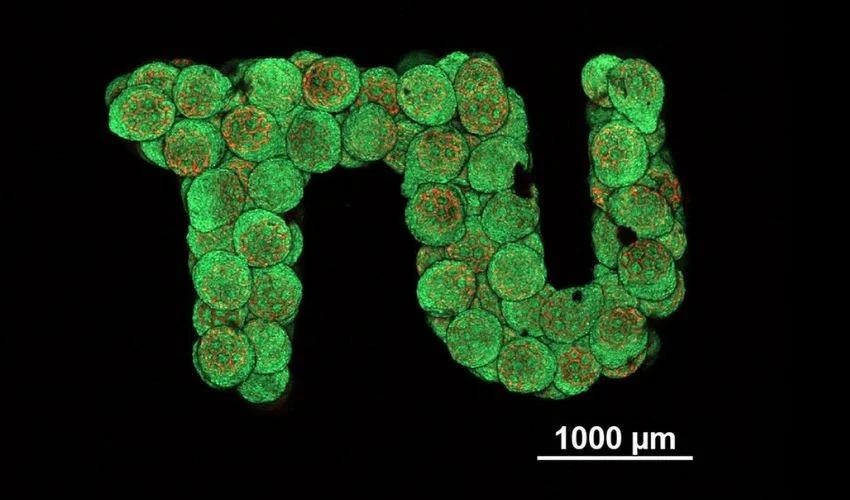

It Is Now Possible to 3D Print Artificial Cartilage for Living Tissue Replacement

3D printing has reached new frontiers in the medical field, as a research team at TU Wien has achieved a breakthrough by leveraging a precise 3D printing process to produce artificial cartilage. This innovation enables the laboratory cultivation of living replacement tissue tailored to specific needs, a crucial advancement for medical applications. Indeed, the hope is that the technology could prove invaluable in scenarios such as replacing damaged cartilage, where precise tissue formation is essential.

The achievement represents a significant leap forward in the medical industry, since the development of cartilage tissue presented numerous challenges prior to the adoption of these precision 3D printing techniques. Previously, attempts made to cultivate tissue in the laboratory using alternative methods often encountered significant complications. The production of larger tissue is particularly challenging with cartilage cells, as a structure is created between the cells in the cartilage tissue that does not allow the various cell spheres to grow together in the correct formation.

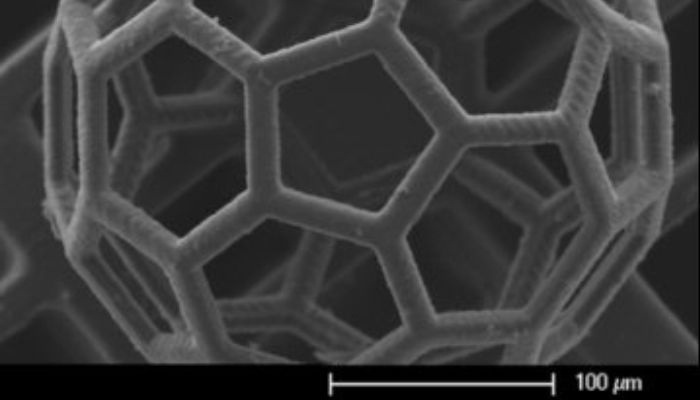

The football-like support structure.

According to one of the study’s authors, Dipl.-Ing. Oliver Kopinski-Grünwald from the Institute of Materials Science at TU Wien, cultivating cartilage cells from stem cells poses less of a challenge. The primary issue lies in the lack of control over the resulting tissue’s shape. This is partly attributed to the tendency of stem cell clusters to change shape over time and shrink. In order to determine the shape of the resulting tissue, the research team at TU Wien is now using laser-based precision 3D printing systems to create support structures for the stem cells.

The Process for Creating the Artificial Cartilage

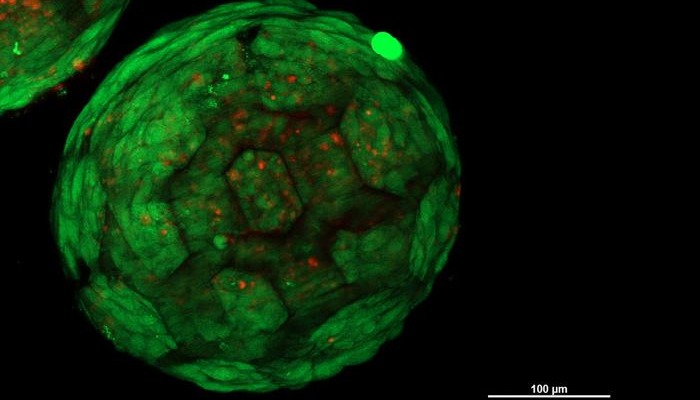

The support structures form dense building blocks that can be used to create a variety of shapes. These structures resemble microscopic cage-like formations akin to mini footballs, each measuring only about a third of a millimeter in diameter. After the structures are formed, they are infused with stem cells that promptly occupy the entire volume of the cage. These cells seamlessly merge, ensuring the absence of gaps and resulting in a uniform, homogeneous, and living tissue.

3D support structure infused with living cells.

The 3D-printed building block elements play a vital role in stabilizing the overall structure. Constructed from biocompatible and degradable plastic, these elements naturally degrade over time. What remains is the fully developed tissue in the intended form, ensuring seamless integration and compatibility with the body’s natural processes. Because of this, researchers were able to reliably produce tissue constructs with uniformly distributed cells and high cell density. According to Prof. Aleksandr Ovsianikov, head of the 3D Printing and Biofrabrication research group at TU Wien, this breakthrough of artificial cartilage would not have been possible with previous approaches.

The advancement in 3D-printed miniature structures extends beyond cartilage tissue, presenting potential applications for various other tissue types. For instance, the prospect of producing larger tissues, such as bone tissue, holds promise for the future. However, as tissue size increases, consideration must also be given to the incorporation of blood vessels to ensure adequate nutrient supply and waste removal. Kopinski-Grünwald explains,

An initial goal would be to produce small, tailor-made pieces of cartilage tissue that can be inserted into existing cartilage material after an injury. In any case, we have now been able to show that our method for producing cartilage tissue using spherical micro-scaffolds works in principle and has decisive advantages over other technologies.”

What do you think of TU Wien’s 3D printed artificial cartilage? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: TU Wien