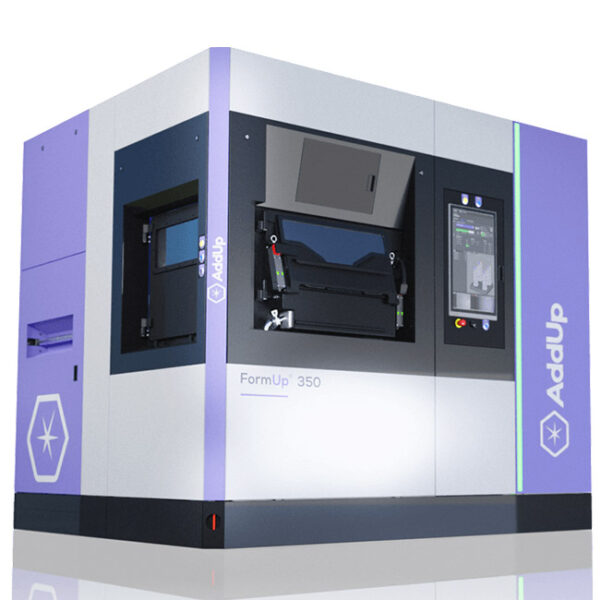

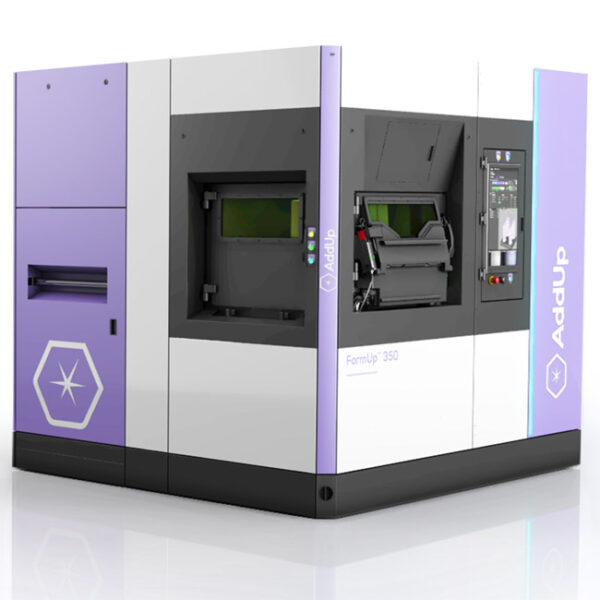

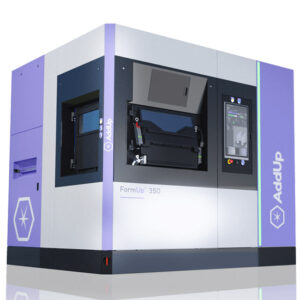

AddUp is a metal 3D printer manufacturer based in France, which was formed in 2015 as a joint venture between Michelin and Fives. It has developed a range of metal 3D printers including the FormUp 350, based on laser fusion technology on a powder bed.

Features of the FormUp 350

The FormUp 350 printer can create parts from stainless steel, nickel, titanium, and aluminum alloys. It has a printing volume of 350 x 350 x 350 mm. The modular machine offers four possible configuration possibilities, each according to a different objective: Starter, Efficiency, Productivity, and Advanced. In addition to that, it can integrate up to four lasers with a power of 500 W.

The FormUp 350 is equipped with a bi-directional coating system that allows spreading the powder up to 40% faster than competitive solutions. Its Autonomous Powder Module also enables automated material management, with a constant supply of material, thus avoiding interruptions in manufacturing.

Precision and Quality

The FormUp 350 metal machine offers complex geometries while focusing on high-performance parts in terms of mechanical and geometrical properties – it achieves dimensional accuracy of up to 0.1 mm. The lasers are accurate to within 35 microns.

This level of performance is not achieved at the expense of operator safety. The French manufacturer has indeed bet on a safe system, with zero risk in terms of powder/user contact as well as in terms of waste disposal. Indeed, on its website, AddUp points out: “Exposure to fumes and fusion residues is also limited, thanks to the automatic passivation filter system that allows for waste evacuation without danger to the user.”