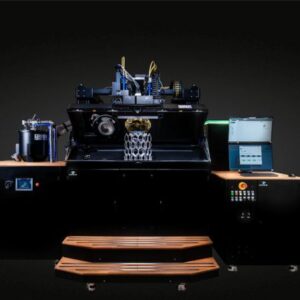

Building upon previous success, Aconity3D, the company with a strong focus on modular machines suitable for a variety of new industrial applications for 3D printing of metals, has unveiled the AconityTWO which promises a greater suite of functionality and configuration than its previous iteration. AconityTWO builds upon the production solutions of the AconityONE, featuring a 400 mm diameter, large-format build platform and an easy-access machine cover for easier maintenance and material changes. It also possesses modularization possibilities for preheating, process monitoring or modified laser configuration.

It can be available with a FOUR-laser system which allows for a complete overlap of all laser sources across the entire build area with variable spot sizes between 80 – 500 µm. The multi-laser setup can also be configured for master-slave operations for the targeted preheating and postheating of localized areas during the build thanks to Aconity’s own 3D scan head technology.