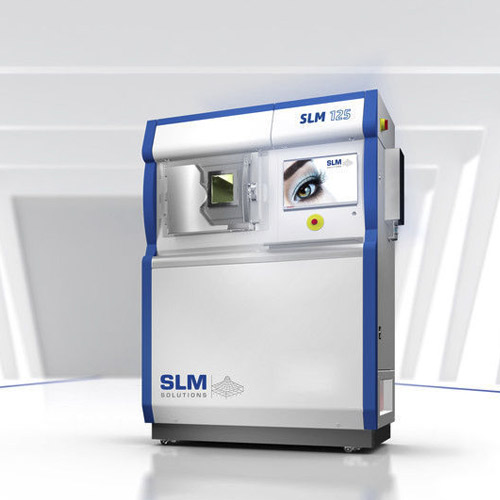

SLM Solutions is a German company that specializes in manufacturing industrial 3D printing solutions, specifically in metal for many years. The company has its headquarters in Germany, but also has offices in several other countries, including France, India, Italy, Russia, China, the United States, and Singapore, as well as a vast network of partners and resellers. SLM Solutions is one of the pioneers in powder laser melting technology and was among the first to develop multi-laser solutions for creating high-quality metal parts. Today, the company offers a range of industrial machines, including the SLM®125, which is its smallest 3D printer.

Characteristics of the SLM®125

The SLM®125 is an entry-level machine that offers a printing volume of 125 x 125 x 125 mm, hence its name, and provides more accessibility than other metal solutions. It uses the powder bed laser fusion process, which relies on a standard 400W fiber laser. According to the German manufacturer, the SLM®125 offers 160% more volume than competing solutions, using 80% less powder. This is because the machine uses an optimized gas filtration system that improves the gas flow.

The SLM®125 is compatible with nickel alloys, aluminum, stainless steel, titanium, and chrome-coal, and can process reactive and non-reactive metals. The machine is equipped with a powder screening system to ensure high-quality printing, which separates oversized particles from those ready to be fused.

The SLM®125 is suitable for tooling parts with integrated cooling channels, such as tooling inserts, and is also popular in the medical sector for the production of custom-made implants, among other things. It is an ideal solution for anyone interested in starting industrial metal 3D printing.