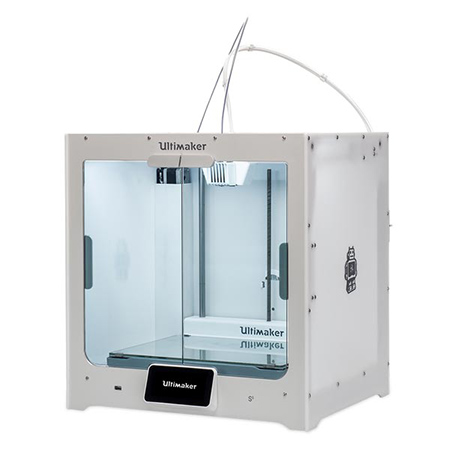

The Ultimaker S5 3D printer, presented for the first time at Hannover Messe in 2018 launched after the Ultimaker 3. It combines a dual extrusion system and improved connectivity, it also allows the use of non-proprietary filaments, and presents a the largest build volume on the Ultimaker range.

What’s new?

This printer has a large build volume, it can produce parts with a maximum size of 330 x 240 x 300 mm (against 215 x 215 x 200 mm for Ultimaker 3). Moreover, it comes with an enclosure and has a 4.7 inch touch screen. Other features of the Ultimaker S5 include end-of-filament sensors, an interchangeable print core system, dual head extrusion, heated glass plate and automatic calibration.

The Ultimaker S5 Pro Bundle

Besides the printer itself there is also the so-called S5 Pro Bundle. Ultimaker has developed an Air Manager solution and a Material Station to optimize material management for the S5 3D printer. The Air Manager solution is a filtration system designed to improve air quality and provide a safer working environment. As for the Material Station, the aim is to enable continuous 3D printing. For example, the user will be able to store and manage materials (up to 6 spools of filament). Additionally, the chamber can keep the relative humidity below 40% while each of the 6 compartments are equipped with a sensor to automatically load another spool when the one used is finished.

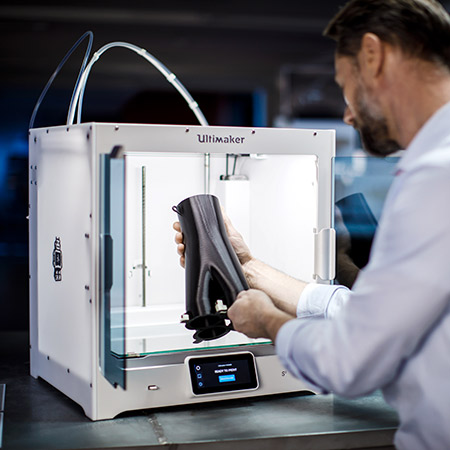

We’ve already tested the Ultimaker S5 3D printer in 3Dnatives’ Lab, check out our test & review HERE.