The E2CF, A High-Strength 3D Printer

The Raise3D E2CF is an industrial 3D printer designed by the manufacturer Raise3D. This version of the E2 has been developed specifically for printing composite materials. It has a number of new features in addition to the well-known qualities of its smaller sibling. These include a high-precision automatic plate leveling system, dry boxes for filaments and a reinforced extrusion and hot-end system.

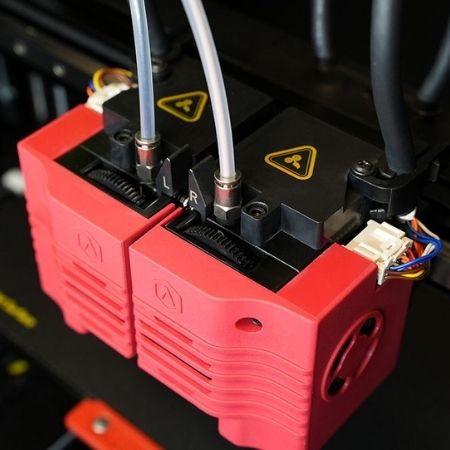

This 3D printer is specialized in printing carbon fiber parts. However, you can also print more traditional materials with it. The E2CF printer is specifically designed to enable the creation of ultra-durable parts, which can be deployed for long periods in demanding applications. To make this possible, Raise3D has equipped its latest machine with a dual-gear extrusion system, allowing it to process hardened components with twice the feed grip force of the E2, with a reduced risk of wear.

Compatible Materials

The Raise3D E2CF is designed for 3D printing with carbon fiber reinforced filaments. To ensure smooth operation and optimal results when using this equipment, Raise3D E2CF supports only manufacturer-validated filaments and printing profiles. These include Raise 3D’s PA12 CF filament, but also third-party materials certified by the Raise3D Open Filament program, such as filaments from BASF or LEHVOS. This list is continuously updated to offer the user a wide range of compatible materials.

Professional Use and Quality

Raise3D E2CF is a professional 3D printer designed to facilitate the whole 3D printing process. To do so, this FDM 3D printing equipment has several features that guarantee the best results and make it easy to use. It is a completely closed 3D printer. In addition, it includes a HEPA air filtration system that helps reduce the effects of fumes and gases derived from extrusion, maintaining a safe manufacturing environment at all times. The Raise3D E2CF has a large print volume: 330 x 240 x 240 mm when printing with a single head, and 290 x 240 x 240 x 240 mm when printing with both heads at the same time. This allows the user to produce complex, high-volume parts with carbon fiber reinforced materials.