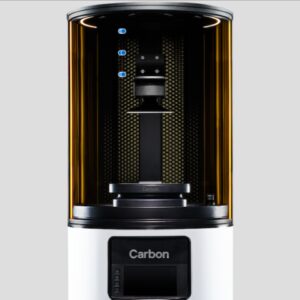

The Carbon M1 is a resin 3D printer developed by the American company Carbon. The company has also launched two other models in the same series: the M2 and the M3. Designed for production, the M1 machine is based on the manufacturer’s ultra-fast DLS (Digital Light Synthesis) manufacturing technology. This trademarked technology uses digital light projection, oxygen-permeable optics, and programmable liquid resins. It is compatible with rigid plastics and rubber-like plastics, and facilitates complex geometries and designs which are not possible with conventional methods such as CNC.

Features of the Carbon M1 3D Printer

This Carbon solution has a maximum build volume of 141 x 79 x 326 mm and is designed to process proprietary photopolymer resins as well as resins from other manufacturers and dual-cure resins that do not require heating during printing. This means the user has a multitude of resins to choose from according to their needs. It is a 3D printing solution with a high production speed. Thanks to the range of resins developed by Carbon, 3D functional parts with different properties can be produced. This gives users the high accuracy, consistency, reliability and material performance of Carbon DLS technology at a considerable price. Users can benefit from the Carbon resin range developed in partnership with Kodak.

In terms of print design, the Carbon M1 supports stl files and users benefit from Carbon’s Design Engine software, which allows them to generate advanced functional lattices in minutes. Furthermore, this software usually eliminates any requirement for manual editing of struts or structures post-generate.

The printer makes extremely accurate parts, with a general accuracy which comes up to 0.002 in. Furthermore, regular software updates mean that the Carbon M1 is continually improving for better prints and a more streamlined user experience. The update history shows improvements have been made, on average, every couple of months since 2020.