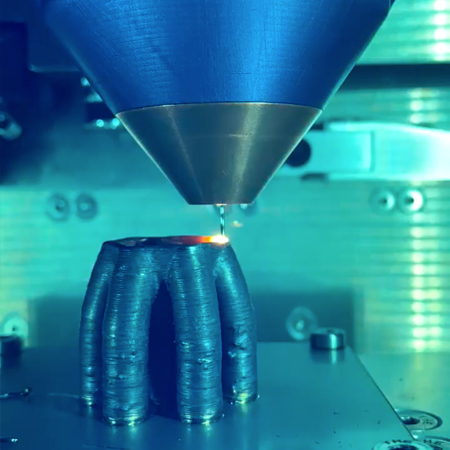

Metal additive manufacturing is widely used at the industrial level by companies that want to achieve high quality and high strength parts. Meltio’s LMD technology is a laser-based 3D printing process that is capable of extruding metal wire, powder or both simultaneously, without the need to change the nozzle. Unveiled for the first time at Formnext 2019, the M450 is unique in the metal additive manufacturing industry due to its wide range of applications and ability to print 100% dense metal parts.

Features of the M450

With a maximum printing volume of 200 x 150 x 450 mm, this 3D printer is compatible with different types of metal such as inconel (nickel-chromium-molybdenum superalloy), titanium (high strength, lightweight and flexible) and stainless steel (corrosion resistance), among others. Meltio’s innovative and patented technology, called LMD, is based on DMLS and WAAM (which itself is a form of DED). This innovative process allows for a halving of the initial investment cost and results to an improvement to overall performance as well as productivity according to the manufacturer. The effectiveness of the technology is based on two main factors: the head has between 3 and 6 lasers integrated, and the nozzle that allows the energy to be focused on the specific printing material.

Who is this Machine Intended For?

Meltio’s M450 is the perfect choice for companies that need 3D printers for metal fabrication. The prices of these types of machines reflect the size of the printing capacity they have, as well as their overall performance. That’s why Meltio’s M450 3D printer was created based on the needs of today’s market, adding value to your investment.