ETH Zurich Develops Efficient 3D-Printed Ceramics for Solar Energy Production

Researchers from ETH Zurich’s Departments of Complex Materials and Renewable Energy Sources have succeeded in producing a solar reactor core from individually 3D-printed ceramics. Solar reactors are used to produce carbon-neutral liquid fuels such as solar kerosene for the aerospace industry. The technology therefore holds a great deal of potential for lower-emission aviation that is made possible through the use of additive manufacturing. More environmentally friendly fuels of this kind can now be produced in greater quantities thanks to the increased efficiency of solar reactors. The project at ETH Zurich is being made possible with funding from the Swiss Federal Office of Energy.

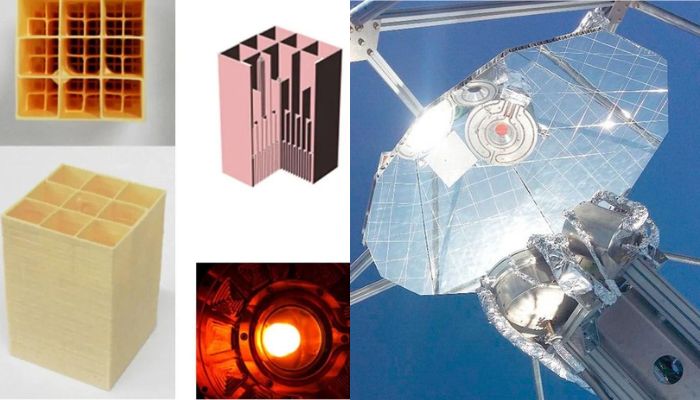

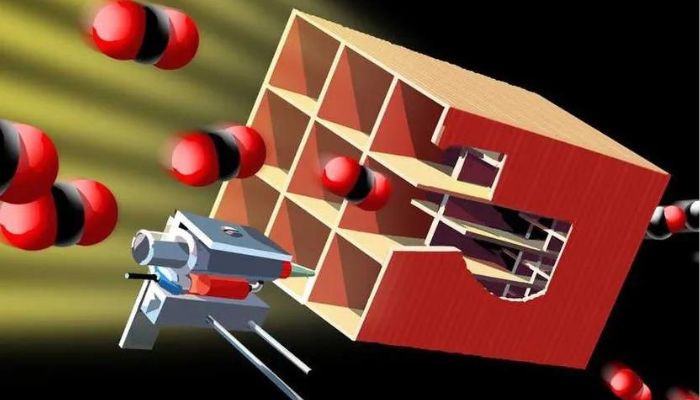

In a nutshell, the solar reactor functions by first being illuminated by sunlight from a parabolic mirror. The new structure of the reactor includes a 3D-printed complex of hierarchically arranged ceramic structures. This opens up on the surface facing the sun and narrows further towards the rear of the reactor, trapping the heat. As the first successful tests at ETH Zurich showed, the entire structure is capable of reaching a reaction temperature of 1500°C due to concentrated solar radiation. In addition, the solar radiation is transported more efficiently into the interior of the reactor thanks to the 3D printed components. As a result, twice the amount of carbon-neutral solar fuel is produced with the same amount of solar radiation compared to previous isotropic structures. The ceramic structures themselves are printed through extrusion from a specially developed paste from the 3D printer. The extruded paste consists of a high amount of cerium oxide particles in order to obtain the most reactive material possible and thus maximize the efficiency of the solar reactor.

3D-printed ceramic structure (left) and solar reactor (right)

ETH Zurich has been researching solar fuels for over a decade and has previously demonstrated the process for their production on the university campus in 2019. The engineers at the Swiss university have also already developed a solar reactor in which the energy of concentrated solar radiation is used to produce synthesis gas (hydrogen and carbon monoxide) through a series of thermochemical cycles to split water and CO2. This in turn is used for the production of liquid solar fuels such as solar kerosene as aircraft fuel. These fuels are CO2-neutral, as only as much carbon is released during their combustion as was previously extracted from the air for the production of the synthesis gas. The structures previously used in the reactor had an isotropic porosity. The sun’s rays hitting the reactor were attenuated on their way into the reactor due to the surface properties. This meant that the optimum internal temperature could not be reached in the reactor, which limited its performance and fuel production.

According to ETH Zurich, their newly developed technology is already highly advanced, which is why the ETH spin-offs, Climeworks and Synhelion, are striving to further develop the technology commercially, market it and collaborate with companies such as Zurich Airport and Lufthansa. In addition, the 3D printing technology of the ceramic structures has already been patented. Synhelion has also already received a license from ETH Zurich. Steinfeld, full professor at the Department of Mechanical and Process Engineering at ETH Zurich, emphasizes: “This technology has the potential to boost the solar reactor’s energy efficiency and thus to significantly improve the economic viability of sustainable aviation fuels“. For more information on ETH Zurich and its research, view their page HERE.

Illustration of the 3D-printed reactor

What do you think of ETH Zurich’s 3D printed solar reactor reactor? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All photo credits: ETH Zurich