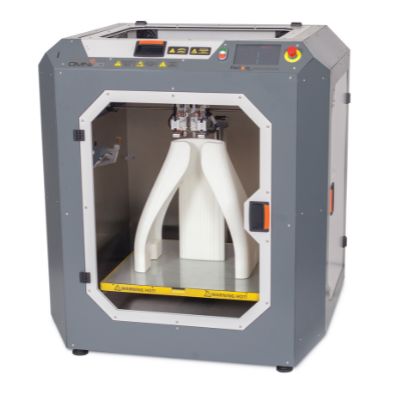

Polish 3D printer manufacturer Omni3D has been steadily making a name for itself in the market for industrial FFF solutions and this particular machine is certainly proof of that. The Factory 2.0 production system is a solution for anyone looking to optimize costs and production time. Moreover, the company further notes that it is ideal for the production of high-resolution finished parts, for prototyping or for small series production. This is at least partly due to its extremely large printable area, with a 500 x 500 x. 500 mm build volume (allowing for the printing of both large items and simultaneous smaller batches).

Features of the Factory 2.0

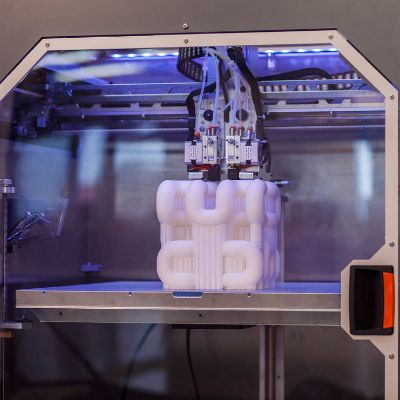

The Factory 2.0 has been designed for industrial FFF 3D printing, joining the company’s other offerings, namely the OMNI500 LITE and the Factory 2.0 NET. As you might expect, all three of these printers have a number of features that make them perfect for industrial FFF. For example, the printer has an enclosed heating chamber for effective printing of industrial thermoplastics which are often subject to warping otherwise. This includes ABS. This is further helped by Omni3D’s patented Cooling System which cools the extruder, allowing it to be used in a heated chamber and providing better control over the dimensional precision of the print. As well as Omni3D’s Air Circulation, used to regulate the temperature of the entire surface of the part by maintaining a constant temperature inside the printer itself.

The machine also boasts dual heads, which can lift when inactive (preventing drip or other issues), thus increasing the speed of printing. The print heads are also able to be controlled thanks to Omni3D Filament Flow Control, allowing for users to control the filament flow, ensuring ensures precision and dimensional repeatability. The Omni3D Head Leveling Control software also helps with this, as it automatically adjusts extruder height. This is complemented by the Omni3D Platform Autoleveling System, an automatic table leveling system that ensure that the printer nozzle will always be at the same distance from the build plate, regardless of its position on the x or axes. Both of which are critical for effective FFF 3D printing with minimal print failures. These characteristics combined with the defined print settings (for use with Omni3D’s materials), make as well for a quick start for the 3D printing and easy operation.

OMNI3D

OMNI3D